— 8 min read

Cost Breakdown Structure: Enhancing Financial Clarity in Construction

Last Updated Jan 24, 2025

Last Updated Jan 24, 2025

General contractors must closely monitor project costs across various categories, such as labour, materials, and equipment, to preserve their profit margins — ensuring that the actual costs incurred during the project align with initial estimates. A lack of transparency in tracking project costs can lead to minor budget overruns in any category, which, over time, may escalate into significant financial issues.

Ideally, general contractors, project managers, and other key personnel would be able to track specific cost categories efficiently, without the need for time-consuming reviews of extensive spreadsheets. This is where a cost breakdown structure proves to be highly effective.

This article explores the intricacies of cost breakdown structures, including their creation and application in managing construction project finances.

Table of contents

Understanding Cost Breakdown Structure

A Cost Breakdown Structure — or CBS — is a string of code that lets stakeholders see what work is happening and how much it costs.

A CBS isn’t a document that lives on its own. Instead, it’s the first step in tracking costs in the appropriate software. With the right accounting solution and the right level of automation, the CBS provides GCs, project managers and other stakeholders with visibility into project costs without anyone having to maintain a cost document manually.

General contractors will typically establish this cost project breakdown format before a project starts. Then, the codes they decide to apply to each cost category can be fed wherever they are needed. That usually means they overlay on the Work Breakdown Structure (WBS), but they can also be fed to construction accounting tools, contracts, change orders, and more. With a CBS, systems can accurately and efficiently exchange information about project costs.

What’s included in a cost breakdown structure?

A CBS can help digitize costs and deliver as much granularity as necessary when evaluating construction project cost breakdown. Stakeholders can get their required level of detail by tailoring the cost breakdown structure to them.

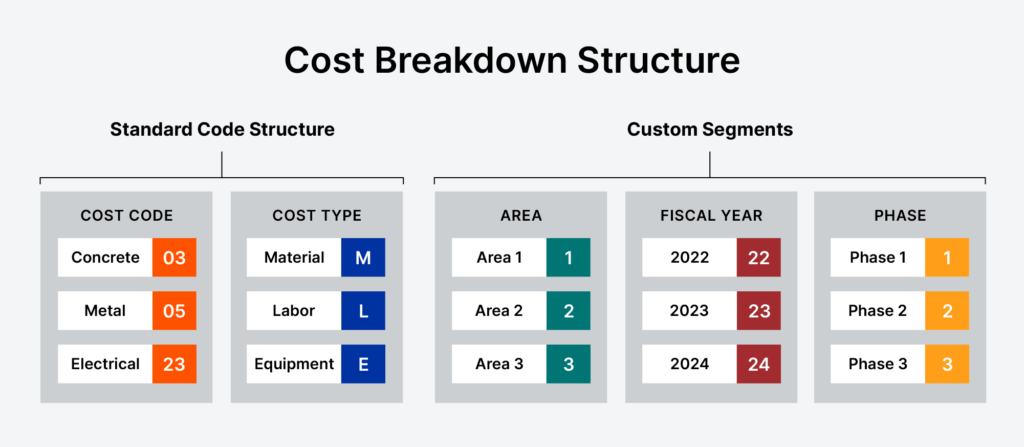

Many will include all of the following components in their CBS:

- CSC (Construction Specifications Canada) cost code

- Cost type

- Area of the project (e.g., specific building or floor of the building)

- Fiscal year

- Project phase

Using this method, contractors can create a string of codes that track both direct costs and indirect costs across a wide variety of categories and scenarios. The CBS helps them keep a finger on the cost of the sticks and bricks — i.e., physical aspects of the build that they can see, feel, and measure relatively easily. But they can also create a cost breakdown structure that enables them to track indirect costs.

With the right segments in a CBS, for example, stakeholders can track the cost of utilities to allow for wash-down between subcontractors or temporary lighting so people can see what they’re working on. They can capture overhead costs like accounting software and contract development and review.

Owners, GCs and project managers have the option to add whichever segments and categories they need to their specific cost breakdown structure. This gives them visibility into any — and ideally, all — costs associated with the project.

Work Breakdown Structure, Cost Breakdown Structure & Resource Breakdown Structure

Understanding the distinctions between a Work Breakdown Structure (WBS), Cost Breakdown Structure (CBS) and Resource Breakdown Structure (RBS) is essential for project management, particularly in the construction industry.

| Work Breakdown Structure (WBS) | The WBS outlines the scope of work needed to complete a project. It is a hierarchical decomposition of the total scope into manageable chunks of work or tasks. It does not focus on costs but on the deliverables and project outcomes. |

| Cost Breakdown Structure (CBS) | The CBS is deeply integrated with the financial aspect of project management, providing detailed allocation of the costs associated with the WBS elements. It is much more than a budgeting tool; it enables tracking of actual versus budgeted costs with high granularity. |

| Resource Breakdown Structure (RBS) | While a CBS details the financial side, an RBS focuses on the categorization of physical or human resources required for a project. It essentially breaks down these resources by type and category, enabling resource planning, allocation, and tracking. |

In essence, the WBS sets the framework for what needs to be accomplished, the CBS estimates and tracks the costs of these tasks and the RBS ensures the necessary resources are identified and managed throughout the project lifecycle.

5 Benefits of a CBS

Though it requires a lot of front-end work, here are five reasons why creating and applying a cost breakdown structure to a project is worth the effort.

1. Informed Decision-making

With a budget, stakeholders can see the forest. But with a CBS, they can see all of the trees. Because costs are broken down into highly specific categories and tracked within those categories, they can drill down to find any information they need. This way, they can make informed decisions not just in this project phase but also as they move forward into future phases and future projects.

2. Transparency

With a cost breakdown structure, everyone with access to the CBS can see all the numbers. They can quickly delineate between labour and material costs, for example, helping them better manage their aspects of the project. All stakeholders stay on the same page about the work that’s happening and what it’s costing.

3. Accurate Budgeting

A cost breakdown structure allows a deep dive into details around project costs with just a few clicks. This is helpful during the project to stay on budget, of course, but it has a major payoff when it comes to analytics and reporting. With this level of granularity, stakeholders can more accurately estimate costs on future projects based on historical data. And that data is already neatly organized for analysis.

4. Improved Cost Controls

CBS overlays with the budget so everyone can see anticipated costs and then compare them against actual costs as they are incurred. This way, key players can detect deviations early. And they won’t just see that they’re over in a certain category, but can drill down to see precisely where overages occur. Consequently, they can adjust more quickly right where the correction needs to be made, helping them keep a better handle on overall project costs.

5. Better Communication

The CBS provides a common language everyone can speak and a source document that can flow elsewhere as needed to monitor costs. Using alpha words to track budgets can create inconsistencies (e.g., “concrete material” vs. “concrete.material”). A CBS reduces the risk of double entry. This keeps everyone on the same page to track both current progress and historical data.

How To Create a Cost Breakdown Structure

Both the CSC-based work type and the cost type should stay consistent across CBS codes since most projects move through the same phases and require some combination of materials, labour, equipment, subcontracted work and overhead.

Beyond that, stakeholders might maintain the same segments in the CBS but adapt them to the specific project. Here’s a table a company might use for one project:

| Segment | Possible Categories |

|---|---|

| CSC Code | 00 (procurement and contracting requirements), 01 (general requirements), 02 (existing conditions), 03 (concrete), 04 (masonry), 05 (metals), etc. |

| Cost Type | M (materials), L (labour), E (equipment), S (subcontracts), O (overhead) |

| Project Area (Building Floor) | 0 (basement), 1, 2, 3, etc. |

| Fiscal Year | 2024, 2025, 2026, etc. |

| Project Phase | 1, 2, 3, etc. |

A Cost Breakdown Example

Because this can get a little complex, we’ll give an example of the simplest type of cost breakdown structure: the MasterFormat divisions from the Construction Specifications Canada (CSC) plus the cost type.

For the cost type, companies assign alphanumeric characters to different cost categories. For example, a company might decide that the cost breakdown structure codes cost types as follows:

- Material: M

- Labour: L

- Equipment: E

- Subcontracts: S

- Overhead: O

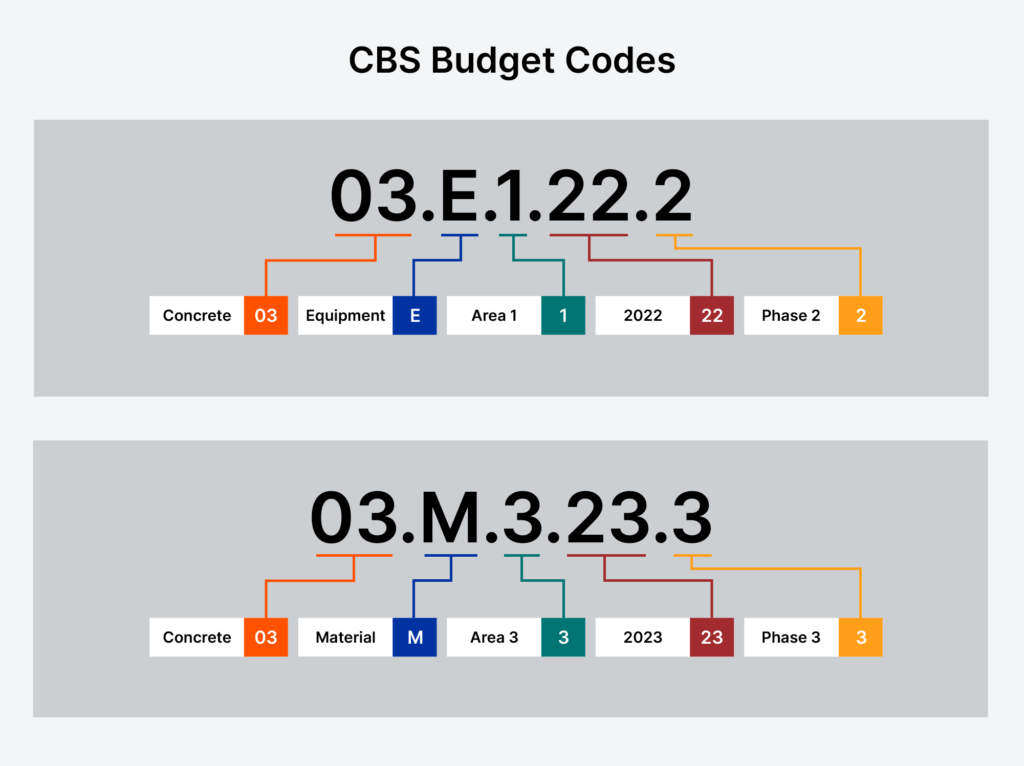

Say a GC wants to create a CBS code for all concrete labour on their project. They would use the CSC code for concrete, which is 03. In that CBS, anything that’s concrete material would get a cost code of 0.3.M. Contractors will often get even more granular by breaking down the area of the project where the work is happening, the fiscal year and the project phase.

The image above shows two examples of how to create a cost breakdown structure. In the first example, the cost is broken down to the Equipment (E) used for Concrete (030) being poured in Area 1 (1) in 2022 (22), during Phase 2 (2) – creating the work breakdown budget code 03.E.1.22.2.

In the second example, the costs are broken down to see the Material (M) costs for Concrete (03) that was poured in Area 3 (3) in 2023 (23), during Phase 3 (3) for the project — making the CBS budget code 03.M.3.23.3.

A Use-Case Example of Cost Breakdown

To show how a CBS can help to deliver improved cost control, informed decision-making, and more, we’ll share a cost breakdown example. One particular project in Edmonton had three funding sources: the property owner, a tenant who committed money to make specific improvements to their leased space and an insurance company paying out after a flood or storm claim.

On this project, the cost breakdown structure included a segment to indicate the funding source. This way, when the general contractor accepted a cost from a subcontractor or delivered a change order, the CBS clearly indicated the appropriate party to pay the cost. All three funding sources had transparency into what they were covering, and the project stayed appropriately organized, eliminating the risk of cost disputes.

Ultimately, when stakeholders want to get a clear construction project cost breakdown, a CBS can deliver the granular detail they need — and it can accomplish that without an overly complex system, instead serving up a common language that can be applied to everything from contracts to change orders.

Categories:

Tags:

Written by

TJ Forbes

16 articles

TJ Forbes is a Senior Solutions Engineer at Procore, specializing in financials products, analytics, ERP integrations, workflows, reporting and accounting solutions. He previously worked as a financial manager and project accountant for Stiles, a commercial real estate firm in Ft. Lauderdale. TJ holds a Masters in Financial Management from Southern Adventist University.

View profileKacie Goff

54 articles

Kacie Goff is a construction writer who grew up in a construction family — her dad owned a concrete company. Over the last decade, she’s blended that experience with her writing expertise to create content for the Construction Progress Coalition, Newsweek, CNET, and others. She founded and runs her own agency, Jot Content, from her home in Ventura, California.

View profileReviewed by

Kristen Frisa

68 articles

Kristen Frisa is a contributing writer for Procore. She also contributes to a variety of industry publications as a freelance writer focused on finance and construction technology. Kristen holds a Bachelor of Arts in Philosophy and History from Western University, with a post-graduate certificate in journalism from Sheridan College. She lives in Ontario, Canada.

View profileExplore more helpful resources

Equipped for Success: The Risks and Rewards of Construction Equipment

Even before written language, humans used tools to build. Contractors couldn’t have built the amazing feats seen and used in everyday life without machinery. From handheld tools to multi-storey tower...

The Percentage of Completion Method Explained

Accounting for income and expenses can present a real challenge for contractors, especially on long-term projects. The percentage of completion method is one of the most common methods of accounting...

What Is a General Contractor?

In the construction industry, a general contractor is the person or company responsible for overseeing a construction project. Property owners will typically hire general contractors to ensure a construction job...

MasterFormat: The Definitive Guide to CSI Divisions in Construction

Often referred to as the “Dewey Decimal System” of construction, the Construction Specifications Institute (CSI) MasterFormat is the industry standard in North America for organizing construction specifications. This system enables...