— 15 min read

Construction Procurement – an Introduction

Last Updated Mar 26, 2025

Last Updated Mar 26, 2025

Procurement is a wide-ranging discipline which commences at ‘Definition of Need’ and terminates at ‘Asset removal’. It considers the strategic and operational approach, by which all the products, materials, professional services and construction work needed to deliver a project, are obtained. The last 20 years has seen huge changes to the responsibilities of procurement professionals, and there is a great obligation to also consider requirements such as environmental legislation, sustainability drivers, modern slavery and social value concerns amongst other factors which are important to society as a whole.

Employing best practice procurement has been proven to improve efficiency, cost-effectiveness, risk management and sustainability and also guards against cost rises caused by supply chain disruption and labour shortages.

Table of contents

Efficiency and Time Management

Effective procurement strategies can significantly enhance the efficiency of construction projects, where profit margins are often well below five percent. But careful and methodical selection of suppliers and contractors can ensure that materials and services are delivered on time, reducing delays that can lead to increased costs. In particular, early supplier engagement has been shown to enhance efficient delivery of the project. In addition, the adoption of advanced procurement methods, such as e-procurement and collaborative procurement, allow for streamlined communication and quicker decision-making. This efficiency is vital in the competitive UK construction market, where timely project delivery is often a key determinant of success.

Cost Management

A well-structured procurement process can help secure competitive pricing for materials and services, allowing projects to stay within budget. The use of frameworks and long-term agreements with suppliers can lead to cost savings through bulk purchasing and reduced administrative overhead. Additionally, effective procurement helps in identifying cost-effective alternatives and innovative solutions, further enhancing financial efficiency. It is important to recognise however, that market factors often drive up the cost of products, beyond the control of the supplier. Collaborative supplier relationships and risk management is crucial to managing costs in these scenarios.

This is where companies can go out of business by tendering for and winning work incredibly cheaply, and making assumptions that they can earn the difference back out of what they call compensation events.

Paula Gray

Supply Chain and Procurement Director

Mott MacDonald

Risk Management

The construction industry is inherently high risk, with a multitude of factors that can impact project outcomes. Procurement plays a crucial role in risk management by allowing for thorough vetting of suppliers and contractors. Establishing clear criteria for selection, such as financial stability, past performance, and adherence to safety standards, helps mitigate potential risks. Therefore, robust procurement processes can include provisions for penalties and performance guarantees that can help safeguard project timelines and quality. A critical role for procurement is ensuring that materials and services are delivered ‘on time in full’. Delivery delays can result in labour downtime and this is expensive to both the contractor and client.

Quality Assurance

Quality is paramount in construction, and procurement is a key element in ensuring that high standards are met. By engaging reputable suppliers and contractors, project managers can maintain control over the quality of materials and workmanship. Effective procurement practices include the development of detailed specifications and the use of quality control measures, which contribute to the overall success of construction projects and the longevity of built assets. Procurement professionals commonly work with organisations audit teams to ensure supply chain members are operating to applicable standards and legislation.

Sustainability and Innovation

Sustainability is becoming increasingly important in the UK construction industry. Procurement processes that prioritise sustainable practices can lead to the selection of environmentally friendly materials and energy-efficient technologies. This not only helps in reducing the carbon footprint of construction projects, but also aligns with private sector client aspirations, and government policies and regulations aimed at promoting sustainability.

When engaging with a client, go to their website and download the sustainability policy and highlight all the things that are important to that client.

Paula Gray

Supply Chain and Procurement Director

Mott MacDonald

Additionally, innovative procurement strategies, such as partnering with suppliers to co-develop solutions, can foster creativity and lead to the adoption of new technologies and practices. This innovation is essential in addressing the evolving challenges of the construction sector, including the need for modern, low carbon, climate resilient and adaptable infrastructure. In particular, modern methods of construction (MMC) practices, have realised great efficiencies for contractors, particularly offsite construction, where modular units are manufactured in factories and craned into place as a finished unit, removing the risk of onsite variables such as weather.

Regulatory Compliance

The UK construction industry is subject to numerous regulations and standards, making compliance a critical aspect of procurement. Effective procurement processes ensure that all materials and services meet legal requirements, industry standards, and client specifications. By maintaining compliance, construction firms can avoid costly legal issues and project delays.

Moreover, February 2025 will see the introduction of the Procurement Act 2023, bringing significant changes to the regulations that govern UK procurement. It aims to “…create a simpler and more transparent regime for public sector procurement that will deliver better value for money, and reduce costs for business and the public sector.” The Government Commercial Function has published a list of FAQ here.

The new procurement regulations are geared more towards the UK building landscape, and also provide a little more flexibility for companies to create their own tendering approach.

Paula Gray

Supply Chain and Procurement Director

Mott MacDonald

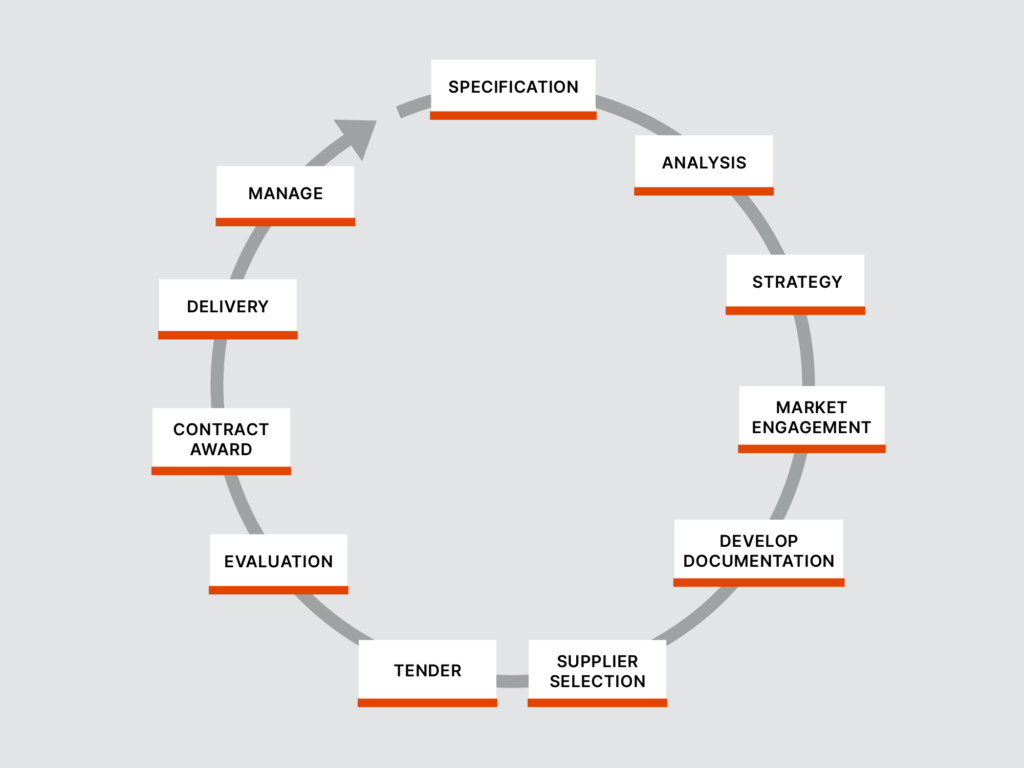

The key steps in the CIPS (Chartered Institute of Procurement and Supply) fixed procurement lifecycle (adapted by Mott MacDonald)

The CIPS procurement cycle provides a structure for organisations to navigate the complexities of construction procurement. It is broken down as:

Specification

Defining the requirements and specifications for the procurement. Taking the water industry as an example, a client would decide the specification of a reservoir including its size and capacity and its associated buildings.

Analysis

This includes the specification, market, stakeholders, risks, and any potential impacts. It needs to examine whether there’s a supply chain for it, potential shortages in products or materials and the impact of things like mineral extraction should it be required.

Strategy

The analysis will generally provide the drivers for developing a written strategy for how to approach the procurement, including considerations like supply chain, scheduling, and risk mitigation. With overseas importers and distributors for example, is a broker required? Will you manage the transactions yourself? Is there going to be a project bank account? Once completed, the strategy goes to all the key stakeholders.

Market Engagement

Engaging with the market to understand capabilities, innovation and potential challenges. This is where you determine the best options based on your needs. If you’re contending with very short lead times, you might opt for either local suppliers, or overseas suppliers who can bring what you need in bulk and store it for you.

Develop Documentation

Preparing the necessary procurement documentation, such as for the procurement strategy and the tender documents.

Supplier Selection

Shortlisting and evaluating potential suppliers. Public sector projects may include sending out a prior expression of interest and information notice on a publicly accessible website.

Tender

Issue tender documentation, outlining what the project is, what is wanted from it, what is expected from suppliers. Respond to queries from an extensive list that includes financial delivery, quality, health and safety, sustainability, ethical perceptions and social value (amongst other areas).

Evaluation

Thoroughly evaluating tender responses and selecting the appropriate supplier. In the public sector a third party evaluates the tender to ensure ethical transparency so it cannot be challenged later over a conflict of interests. Responses must be clearly documented on scoring rationale with meetings commonly recorded.

Contract Award

Awarding the contract and managing the standstill period. Between evaluation and contract award is a stand still period, which is currently 10 days. When the new procurement legislation (Procurement Act 2023) comes into force in February 2025, it will be adapted to eight working days. If the award hasn’t been challenged it can go ahead.

Delivery

Project delivery phase where construction works commence and see it taken through to completion.

Management

Contracting management. If a supplier, for example, has provided an electrical control centre then it would be installed and tested. But ongoing supplier relationship management would be required for maintaining that product. Most UK built assets also have a defects period that can run for several years.

To implement this cycle effectively and ensure a holistic approach, it is important to:

- Involve procurement experts from the very beginning, collaborating closely with engineering and commercial teams.

- Consider all aspects of the procurement, including sustainability, carbon reduction approaches, opportunities for enhanced efficiency, risk, social value and stakeholder management.

- Engage extensively with the market to understand opportunities, capabilities, constraints, and potential disruptions.

- Develop a comprehensive procurement strategy that addresses all relevant factors in alignment with the project's objectives.

- Ensure thorough documentation, evaluation, and contract management to maintain transparency and mitigate risks.

- Each project will have a different approach and the procurement cycle needs to be proportionate to the project, whether it's a one-off or a multi-year scheme. The steps in the cycle can be emphasised or de-emphasised as needed. Align the cycle with the client's specific requirements, particularly around sustainability.

The key factors to consider when selecting appropriate procurement methods and contract types include:

- Micro and macro factors: Micro factors are those within the project environment that can be controlled, such as management of funds. Macro factors are external influences that cannot be controlled, for example government legislation.

- Stakeholder requirements: Be certain you understand the differing needs of all stakeholders, including the client, end-users, and regulatory bodies. Creation of a reporting and communication framework is important, to achieve collaborative working.

- Project characteristics: The size, duration, complexity, and location of the project are all determining factors as well as the type of work being undertaken (e.g., new build, renovation, infrastructure).

- Contractual and legal considerations: Compliance with relevant regulations and procurement rules, especially for public sector projects with the forthcoming Procurement Act 2023, is paramount. Due consideration must also be given to relevant contractual mechanisms, such as pain/gain share, key performance indicators, and additional clauses such as for social value and measured carbon. The NEC suite of contracts is the most commonly used in today’s construction environment, and careful selection of clauses is paramount.

- Market conditions and supplier capabilities: Key issues include the availability and capacity of suitable suppliers and the level of competition and consequent market interest in the project. In the United Kingdom today, there are high levels of planned infrastructure investment and the concurrent nature of these and the impact on supply chain capability and capacity, should be carefully considered.

Shape the Future of the Built Environment at Procore's Construction Summit

Engage with construction leaders and discover the latest technology and best practices that are driving change across the industry.

Typical Procurement Routine

Effective procurement and tendering are crucial for ensuring successful project delivery. The choice of procurement route can significantly impact project time, cost, and quality. These are some of the common tendering procedures and procurement routes commonly used in the UK:

Traditional Procurement

This conventional route is where the client appoints a designer (architect/engineer) to develop the project and subsequently invites contractors to tender for the construction work. It requires separate contracts for design and construction, presents a clear delineation of roles and responsibilities and allows for competitive bidding based on detailed designs.

Often a lump sum contract is used with this increased certainty as they specify a fixed price for the entire project. They are straightforward and allow for clear budgeting but require thorough planning and design upfront. Any changes typically lead to renegotiation.

While its advantages are a high level of control over design along with competitive pricing from contractors, its disadvantages include longer project timelines due to sequential processes and a greater potential for disputes between design and construction teams.

Design and Build

This route has become increasingly common over the last few decades. It combines design and construction under a single contract that apportions a greater degree of risk from client to contractor under a fixed price. The sees the client define the requirements, and the contractor responsible for both design and construction.

This single point of responsibility reduces risks of disputes and often results in faster project delivery as design and construction can overlap and it streamlines communication and decision-making. But with this comes less control for the client over the design process and the potential for compromise on design quality.

Construction Management

In this model, the client appoints a construction manager who acts as an advisor and oversees the construction process while multiple contractors are employed to carry out the work. It offers the client more control and flexibility and features work being tendered in packages.

This greater degree of flexibility can make for a more agile, adaptable project during construction, and can also lead to faster project delivery. But it does mean a higher administrative burden for the client and possible cost overruns if it isn’t managed effectively.

Management Contracting

Here, the client provides a design, and the contractor manages its execution. While similar to construction management, the management contractor is responsible for both the management and delivery of the project the direct employment of subcontractors.

Its benefits include early contractor involvement where specialist supply chain knowledge and expertise can enhance project outcomes. It also offers better cost control and risk management. Weighed against this is the cost of management fees and the requirement for robust client oversight to ensure quality.

Framework Agreements

This route is favoured by the public sector and involves long-term partnerships with a selected raft of contractors, consultants and other suppliers to deliver multiple projects over a specified period, with pre-agreed terms and conditions. It also flexibility of delivery resource over the period of the framework as differing project needs arise.

While this approach can result in cost and time savings through pre-negotiated rates and deeper relationships with supply chains, it also limits competitive bidding for each project and the potential for complacency if not managed correctly.

Joint Ventures

Generally abbreviated to ‘JVs’, these involve two or more parties — such as two contractors or two consultants — collaborating on a project, sharing risks, costs, and profits. This is useful for large projects requiring diverse expertise and is often used to deliver major infrastructure such as HS2 in the UK.

Tendering Procedures

Open Tendering

Any contractor can submit a bid for a project, promoting maximum competition, which encourages wide participation and often results in competitive pricing. On the downside, this may lead to a large number of unsuitable bids and a time-consuming evaluation process.

Selective Tendering

The client pre-qualifies contractors based on specific criteria before inviting them to tender. This ensures only capable contractors are invited to bid, enhancing project quality. However, this reduces competition, potentially increasing costs, and pre-qualification processes are often a sizable time and cost burden for contractors.

Negotiated Tendering

This is often used for complex projects and involves a client negotiating directly with just one contractor or supplier, with whom it generally has a prior relationship. It makes room for flexibility in terms and conditions and will normally lead to quick resolutions as issues occur. But without competition, it can lead to a lack of transparency and perceptions of favouritism.

Two-stage Tendering

A two-phase process where contractors submit initial bids based on outline designs, followed by detailed submissions once selected. This can mean cost reduction through more accurate and competitive pricing. Also, early contractor involvement, which can mean better risk management and innovation, and the fostering of collaborative working relationships. But it does come with an extended timeline, along with added complexity in managing both stages.

It is important to note, that with the advent of the Procurement Act 2023 that will come into force in February 2025, some changes will be made to these options, in the public sector environment.

Paula Gray

Supply Chain and Procurement Director

Mott MacDonald

Sustainability

Sustainability has emerged as a critical factor in procurement over the last 10 years. Prior to this, the emphasis was more towards health and safety and environmental considerations. However, because ‘sustainability’ often means different things to different people, procurement professionals should ensure sustainable practices are aligned with client policies and global best practice.

To cater for this, be certain you understand the client's sustainability policies. These can often be found by reviewing the client's website and sustainability policy to identify the specific sustainability goals and requirements. Having established these priorities, incorporate them into the procurement strategy. This may involve incorporating sustainability-related questions and requirements into the tender process.

In addition, align your sustainability efforts with the 17 United Nations Sustainable Development Goals (UNSDGs) This will ensure the procurement approach supports the broader sustainability agenda and provide informed recommendations to clients.

Remember, one size doesn’t fit all, so tailor the approach for the client, sector and the specific project requirements to ensure a holistic approach.

Emerging Digital Tools and Technologies

There are myriad digital tools and technologies that can improve procurement and project management. They can improve the efficiency, transparency, and overall effectiveness of their procurement and project management processes, leading to better project outcomes and increased competitiveness.

These tools include:

BIM (Building Information Modelling)

BIM enables in-depth detailing of physical assets which enables better planning, coordination, and asset management. BIM can improve procurement by facilitating data-driven decision-making, enhancing collaboration, and streamlining the exchange of information between project stakeholders. Its use leads to improved efficiency, quality, and traceability throughout the procurement and project delivery processes.

The data tagging that accompanies a BIM design means that all of the information pertaining to an installed product and its components is available digitally. This particularly benefits future asset management and maintenance/replacement of parts.

Paula Gray

Supply Chain and Procurement Director

Mott MacDonald

Tender Management Software

Tools like Jaggaer are used to manage the tendering process, from publishing opportunities to evaluating responses. These specialised software solutions can help streamline the tendering procedures, improve transparency, and ensure compliance with relevant regulations. A number of tender systems exist across the public and private sector.

Supplier Management Platforms

Platforms like Achilles, Constructionline and others, are used to manage supplier data, accreditations, and performance, providing a centralised system for procurement teams. These tools can enhance supplier relationship management, risk assessment, and the overall procurement assurance process.

Enterprise Resource Planning (ERP) Systems

ERP systems, such as SAP (systems applications and products in data processing), offer integrated procurement modules that can help manage budgets, track spending, and automate various procurement activities. These systems can provide a more rounded view of the procurement function, enabling better decision-making and financial control.

Digital Twinning and Simulation

Digital twins provide a virtual representation of an object or system to accurately reflect a physical object, such as a built asset. Incorporating elements such as data tagging and performance simulations, they lead to more informed decisions.

With digital twins, users can see a visual demonstration of how an asset will be constructed, and how it will engage with its surroundings, helping them to understand potential risks or issues which may occur.

Paula Gray

Supply Chain and Procurement Director

Mott MacDonald

Categories:

Tags:

Written by

Damon Schunmann

View profilePaula Gray

View profileExplore more helpful resources

Construction Document Software: Essential Tools for Project Success

Construction projects depend on extensive paperwork, including designs, contracts, RFIs, and compliance records. A single misplaced document can trigger delays, disputes, or compliance violations. Despite increasing digital adoption, many teams...

Construction Planning: A Guide to Successful Project Execution

Every successful construction project begins long before the first brick is laid. Indeed, behind each structure – whether a towering skyscraper or complex infrastructure project – lies a carefully crafted...

Leveraging Analytics for Better Financial Forecasting in Construction

Financial forecasting is a difficult task in any industry. In construction, where companies need to manage volatile material costs, labour shortages and variation orders on a daily basis, fluctuations in...

Strategies to Prevent Rework: The Importance of Clear Instructions

In construction, “rework” is the dreaded process of redoing tasks due to mistakes, quality issues, or safety concerns. This unnecessary work drains budgets through wasted materials and labour while causing...