Building Information Modelling (BIM) is increasingly being specified by government, institutional and large commercial clients. However, the adoption of BIM lags among the small to medium enterprises that comprise most businesses in the global construction industry.

Below are some common myths about BIM that are often a barrier, and here’s why you should leave those concerns behind.

Myth #1 – BIM is only for large projects

BIM can deliver time, cost, and quality benefits on projects of any size. For example, it is challenging in smaller projects to ensure the coordination of risers, including their size, locations, and how they interface with the building. A BIM model makes this process of coordination and necessary clash detection far easier.

“We have used BIM on smaller Class 2 projects, and the benefit they provide is the assurance to the builders that the project works, and they will not have any issues,” said Daniel Reincastle, National BIM/CAD Manager for leading global multidisciplinary engineering consultancy Cundall.

Cundall recently worked on a small apartment complex where the balcony drainage and interfacing it with the building risers would have been difficult without BIM.

“With each level being different, this made the coordination a challenge. With the aid of BIM and working in BIM360, we were able to coordinate this efficiently and come up with some innovative solutions for the development. The Builder was engaged with the process and was able to assess the cost impacts of options and speed to deliver the outcomes,” explained Reincastle.

This was crucial for the cost-conscious client, who was managing the project to a very tight budget.

Myth #2 – BIM adds to project costs

“This couldn’t be further from the truth,” said Reincastle. “BIM can be an aid to everyone involved in providing an outcome which is cost efficient and effective.”

Rework, variations and defects all add to project costs. However, a BIM model can help reduce risks and deliver bottom-line savings on wasted materials and labour.

“From a subcontractor perspective, a BIM model vastly outweighs reading 2D plans. Using tools like Navisworks can help you work through issues and concerns and resolve them before even commencing on site or ordering material and equipment. This is not only cost-saving but can significantly reduce time and on-site waste,” said Reincastle.

Myth #3 – BIM adds to everyone’s workload

Construction is a time-conscious business. Adopting a new digital platform and then using it effectively is always a concern for SMEs in terms of the potential new workload involved. However, time spent upskilling in BIM pays off in time saved throughout the project lifecycle.

“Collaborating over a platform such as Revizto to outline issues and RFI’s is a huge time saver. For one, you don’t have to be in the same room to collaborate, but you can still highlight concerns and resolve coordination issues,” explained Reincastle.

“By having a digital model and the correct information in it, a contractor can basically tear down the requirement of what’s needed onsite to complete a task and meet expectations without unforeseen hidden surprises, which always seem to pop up.”

He further explained the added benefit for safety because a BIM model gives the project team the ability to “walk the site virtually” before commencement and highlight possible risks and concerns.

“You can also manage site safety as you can design out any risks flagged on the project with the team constructively and cost effectively,” added Reincastle.

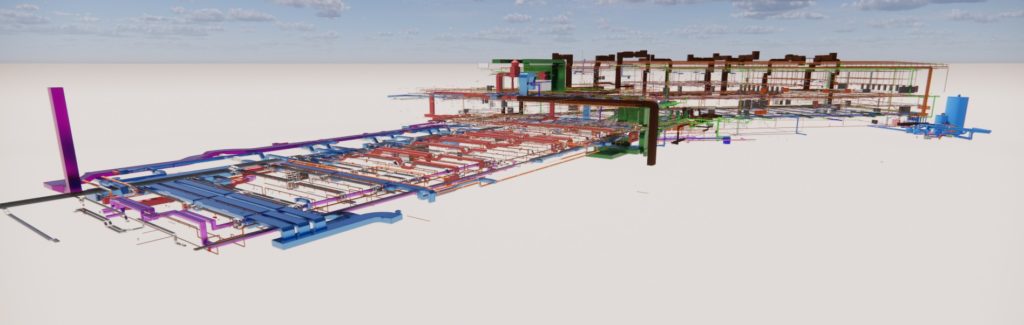

Cundall’s use of BIM on projects at Sydney Airport, including the Under Counter Check-In, is an excellent example of how it delivers value.

The project required replacing the existing baggage handling system located in the ceiling void in the arrivals hall at the international terminal. It also included providing a new service walkway for access and maintenance of the system.

“They had upgraded the ceiling two years earlier and didn’t want it modified. This meant significant services diversions and relocations of the existing services,” explained Reincastle.

Cundall managed to develop a solution to divert the services and coordinate the requirements. This not only avoided impacting the ceiling design but also accelerates the delivery program and improved staging.

“This digital design process resulted in a saving of approximately $2M in construction cost to the end client,” Reincastle said.

Myth #4 – BIM is difficult to understand

Cundall undertakes extremely complex, high-stakes projects around the world. Reincastle says the use of BIM and BIM360 on all scales of projects is key to successful delivery.

“These tools allow us to collaborate efficiently whilst also allowing clients, collaborators and end-users to visualise their project and how any desired changes may impact their final design.”

BIM models can also be automated to speed up design and incorporate changes by modifying design parameters to resize systems. This aids a builder to ascertain any design change impacts visually and work collaboratively with their teams to find the most efficient and cost-effective way to manage the outcomes.

“Enabling engineers and builders to visually ensure their projects are compliant with standards and that the size and complete designs, which are compliant with NCC and Section J requirements, is a significant advantage.”

Using BIM means being able to show a client, subcontractor or other relevant party what is happening and why it is happening.

Myth #5 – BIM is just a 3D set of plans

BIM is often used as a blanket term for Revit, AutoCAD Architecture, ArchiCAD, etc. The real power of BIM goes way beyond creating 3D models. The model can be used as a tool in resolving coordination prior to commencing on site. This applies not only to greenfield sites, but also for brownfield sites where there is a live operational environment for refurbishment projects, and staging works that need to be fine-tuned.

BIM is especially helpful in developing staging plans and methodologies that are visible and can be viewed in 3D.

“This enables the contractors to understand the design intent and staging and provide cost certainty for the project prior to commencement,” said Reincastle.

This application of BIM is known as 4D BIM, and it allows the project team to break down the model to better understand how to stage the construction.

“BIM can also allow for the automation of equipment schedules and materials which again allows builders to quickly generate required schedules and complete take offs,” said Reincastle.

Taking the “plethora of information” from 3D and 4D to give an accurate price is classed as 5D BIM—and it can be used up-front for pricing.

BIM also delivers value on project completion. The BIM information can be used throughout the life cycle of the building integrated with the BMS (Building Management System) to record and help with the ongoing maintenance of the building.

“BIM can be a very powerful tool, and it is not just a 3D drafting software. It can be so much more—and the more builders appreciate its value, the more they can finetune and improve how they operate.

“Collaboration with digital tools is the way forward; it is not a scary beast or an expensive option to consider. When CAD was introduced in the early ’90’s, early adopters of the technology were able to reap the benefits. As we rapidly move into a fully digital design and construct environment, the sooner all builders work in this way, the more benefits they will see.”

Leave a Reply