I know what you’re thinking. “CAD? That’s for architects and engineers, right? It’s not for construction folks. We just get the PDFs of the construction documents and make do.”

Well, that’s how it was for many years. Things have changed, though, and more and more construction firms are making the move to simple 2D CAD systems. With CAD, they can reduce the number of RFIs they need to submit, check spatial relationships in real time, and do their own site layout and staging. They can even create detailed as-builts for client turnover and facility control as a value-add for their clients.

Now, I’m not saying you’re going to have a full-blown, in-house design staff. But having people in your company who can open DWG files and get measurements or check elevations that aren’t labeled can save you a whole lot of time.

Some basic processes are applicable to any construction firm, whether you’re a bonded general contractor or a specialty subcontractor. CAD can potentially be a huge time and money saver for you. Consider the simple problem of getting an unlabeled distance or elevation. If you need to submit an RFI, it can delay your job for days. All just waiting for an answer you could get in 10 seconds within the CAD file.

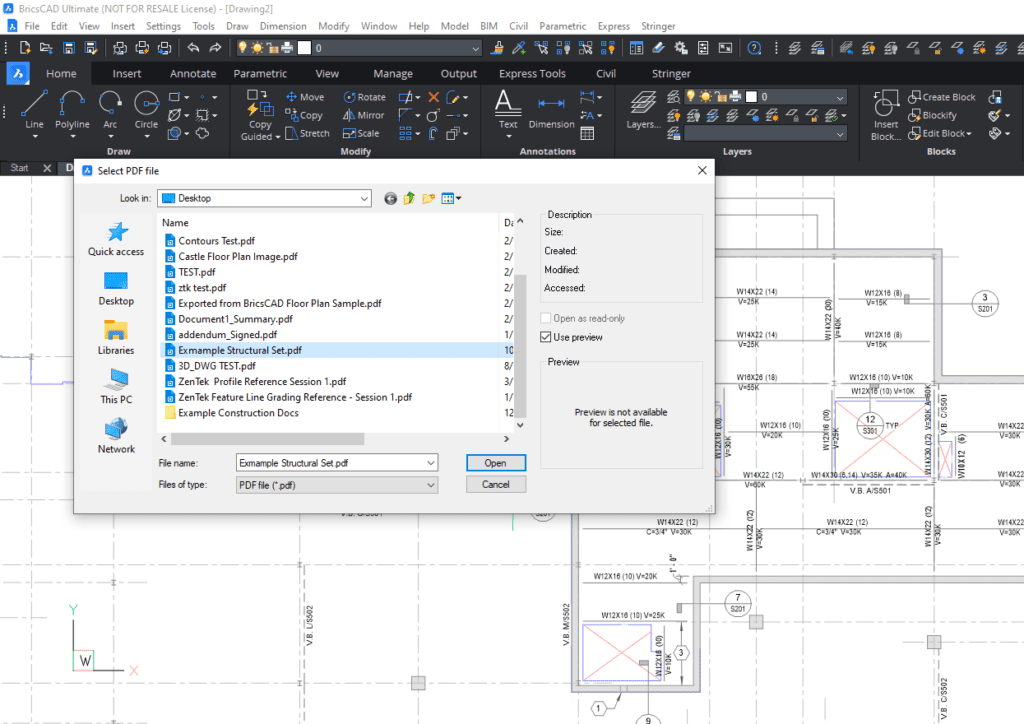

Now, you may be thinking that you don’t always have the DWG files, right? The designers don’t always give access to those. However, with modern CAD systems, you can do what’s called a PDF Underlay. You can import any PDF right into the CAD system and scale it up so you can take any measurements you need. Not only that, but better CAD systems allow you to do a PDF IMPORT, which will actually convert the PDF linework to actual vector CAD linework. That means you can use the original PDFs as a start point for in-field changes, as-builts, or even as alternate suggestions you want to submit to the client or designer.

These methods give you amazing flexibility in creating your as-built and submittals. One lets you draw to scale on top of the PDF, while the other lets you directly edit the file in its native format. Either can be a huge benefit for construction folks.

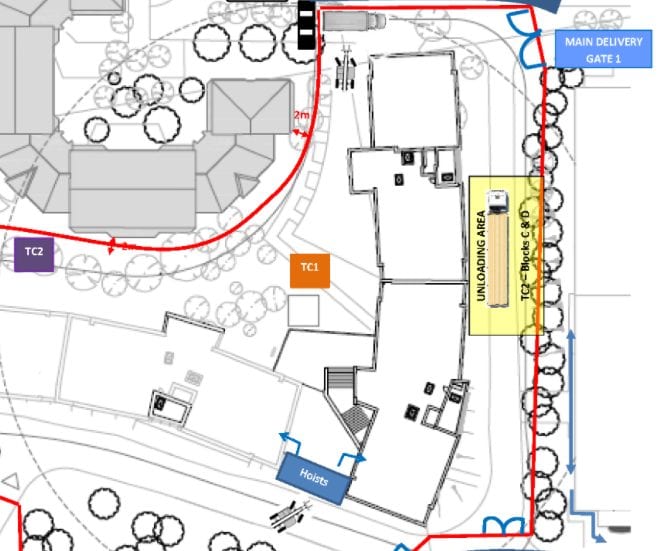

Site access, control, and staging planning is another ideal area for basic CAD use. General contractors need to locate site trailers, power connections, site access control, and even designate material storage and stockpile areas long before the job can even get underway. CAD also lets them take out the time-consuming and often frustrating job of determining what size crane/truck/equipment they can get on-site between existing structures.

With a solid CAD person in-house, getting these answers and handling all your phasing/planning tasks becomes far easier and much more accurate than relying on paper documents and a scale.

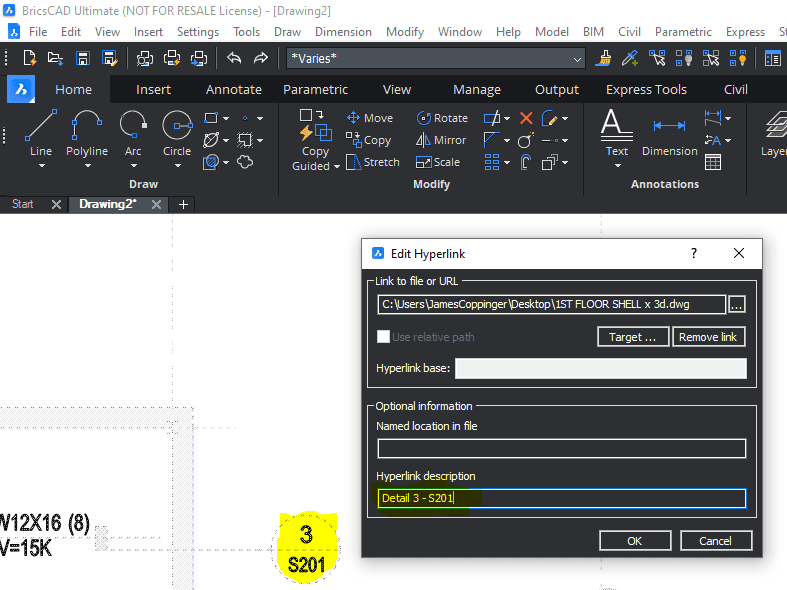

Another CAD tool I’ve seen a lot of construction folks taking advantage of is the ability to hyperlink CAD items to other files. With a modern CAD system, you can link any item—like the fence line— in the CAD file to the installation detail sheet for quick access, to the fence installer’s quote, to the project schedule, or even the manufacturer’s website or a specification section. You can tie all the necessary information on your project into a single master control plan. All the information would be just one click away. You’d never again need to spend countless hours searching for specific information over the lifespan of your project.

These ideas are just the tip of the iceberg. You can use CAD to automate quantity takeoffs, item counts, compare drawing revisions, even overlay drawings for conflict resolution. If you want, you can even get involved in more advanced CAD features to handle things like cut/fill volume calculations or 3D spatial relationships between objects in the real world. The level of CAD use really depends on your firm’s specific needs.

Look, I realize construction firms can be hesitant to encroach on a field that’s been traditionally seen as a design function, but we’re not talking about teaching your people to be architects. We’re talking about getting basic information and tools you need, quickly and easily. Another important thing to note here is that training your staff to use basic levels of CAD is very easy and affordable. The CAD software can pay for itself just with the time savings on a single project.

Don’t let the CAD acronym frighten you. At the end of the day, the CAD system is just one more tool in your toolbox. It’s no different than a hammer or a tape measure. It’s there for you when you need it, both to get you the info you need and to make your life easier.

Leave a Reply