As a result of COVID-19, there has been unprecedented disruption of construction projects across the globe. Many pandemic-related items are out of our control and are best managed by closely monitoring, analyzing, and responding to them. There are, however, other project risk issues that we can control. One of the them is the over compression of project schedules.

Over compression of a project’s schedule is much more common than one would think and typically results in considerable amounts of unnecessary costs related to inefficiencies, delays, and disputes. This is a problem the construction industry has fought for decades, one that has resulted in billions of dollars in wasted spending year after year, and will be many times worse if implemented throughout the pandemic.

The purpose of this article is to be helpful in guiding stakeholders to understand schedule compression, when and how it occurs and how to recognize when a schedule has been over compressed and leading a project down a bad path.

What is Compression and Why Does it Occur

In simple terms, compression in construction occurs when the decision is made to complete the remaining amount of work in less amount of time than originally planned. It usually results from decisions to push off future work with float, or accelerate critical and near critical path activities in an attempt to mitigate historical delays. Compression of schedules is common in construction because there are a lot of moving parts, tight budgets and the execution of project activities rarely goes as originally planned. Not to mention, the industry as a whole consists of optimistic people with engineering mindsets and can-do attitudes.

In addition, incorporating compression into the construction schedule can be a very effective way to manage a project – if done right. However, and unfortunately, most of the time compression is not managed appropriately, leading to over compression and impacting budgets, timelines, quality and relationships. The fine line of managing acceptable levels of compression and over compression is unfortunately the tipping point for a project that is managed very well and one that goes sideways. Therefore, finding the tipping point of acceptable levels of compression in a schedule is instrumental in project success.

Calculating the level of compression in a schedule serves as a key indicator of risk associated with inefficiencies, delays, overruns, claims and ultimately the reasonableness and viability of the schedule. The higher the level of compression, the greater the risk.

So, as we enter into a new world of construction impacted by COVID, it is in all stakeholders’ best interests to understand the compression of the schedule in order to ensure acceptable compression levels exist. Focusing on this one metric alone could end up saving the industry billions in unnecessary spending.

How to Calculate Compression on a Construction Project

As previously stated, compression analysis is essentially a gauge of how much more work we intend to do in the remaining time left – and then comparing that to the original plan. Therefore, in order to do this effectively, one must obtain and analyze project schedules and then perform the following steps:

- Calculate the current “earned” percent complete on the project, as per the most recent schedule update.

- Calculate the remaining duration of a project as per the most recent schedule update. Calculate in “calendar days” by adding up number of days between the “data date” of the most recent schedule update and the estimated project completion date (as indicated in the schedule).

- Determine the date in the original baseline schedule when the project should have achieved the “earned” percent complete that it had achieved to date (as per the most recent schedule update).

- Calculate the remaining duration of the project in the baseline from the date which the project should have achieved the “earned” percent complete (Step 3) and the planned completion date in the baseline schedule.

- Divide the planned remaining duration calculated in Step 4 with the current remaining duration obtained in Step 2 to calculate the Compression Index.

- Subtract 1 (or 100%) from the Compression Index to determine how much less (or more time) is allocated to completing the remaining work as compared to the baseline schedule.

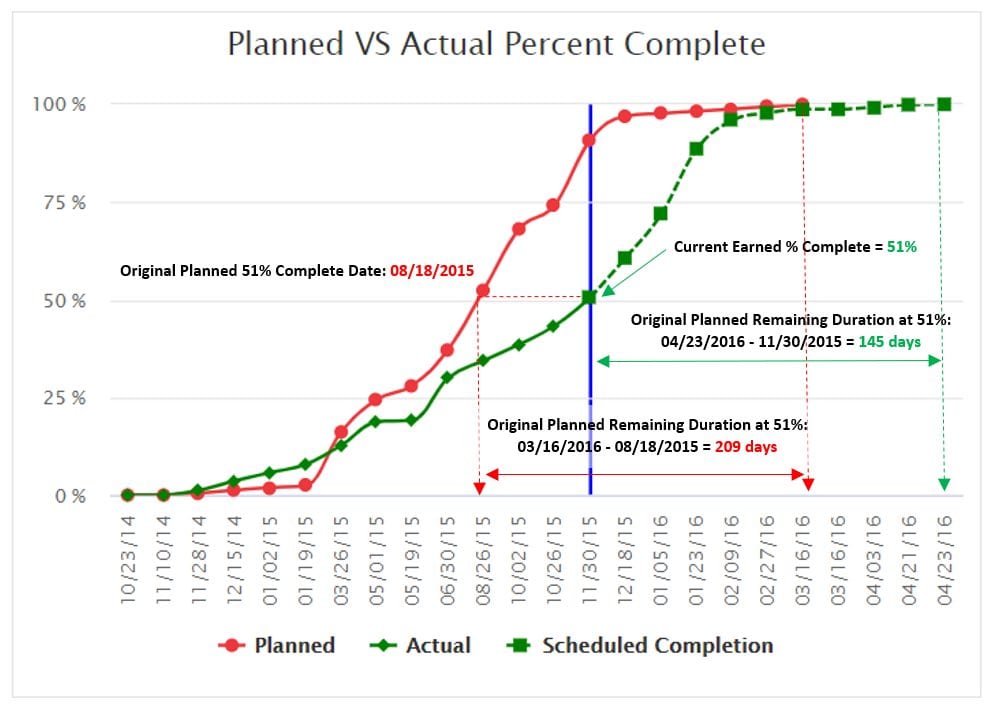

See example below and follow on calculations for a visual and mathematical representation of how to calculate a compression index using the planned versus actual progress curves. *

In the example above, the data date is 11/30/2015, the actual percent complete at the time is approximately 51%, and the estimated completion date is 4/23/2016 (or 145 calendar days from the data date). According to the planned progress curve, the baseline schedule indicated that 51% would be achieved around 8/18/2015 and the estimated date of completion per the baseline was 03/16/2016 (or 209 calendar days later).

The Compression Index is equal to 209 calendar days / 145 calendar days, or 1.45. By subtracting 1 from the Schedule Compression index we determine that the schedule indicates that the remaining work will need to be completed in 45% less time than the original baseline.

Once the Compression Index is calculated, one must determine what an acceptable level of compression is for their particular project. The rule of thumb at SmartPM is that anything over 15% is worth taking a closer look at, especially on schedules that seemed aggressive to begin with.

Determining How and When a Schedule Became Compressed

In order to better understand how a schedule became compressed, one needs to first understand the various ways in which compression is achieved in a construction schedule:

- Consuming float by choosing to delay the start of non-critical work activities that could otherwise start.

- Mitigation of Historical Critical Path Delays through changes made to the schedule on critical and near critical path activities.

- Adding scope to the project through change orders without adding time to the schedule.

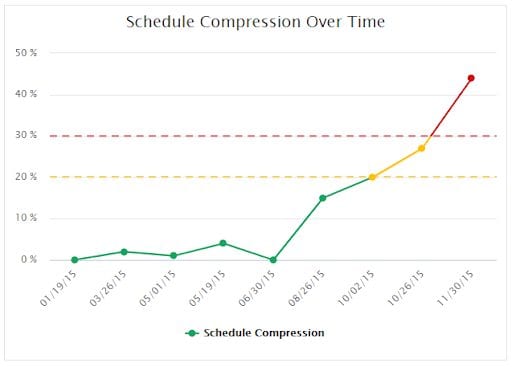

In order to better understand how a specific schedule became compressed, it will first take an analysis of compression over time using the various updates between the issuance of the baseline schedule and the current schedule update as a basis for calculating compression at each update (using the same methodology outline above). An analysis of compression over time assists in pinpointing the period(s) of time where decisions were made to compress the schedule, which can then be further investigated to be deemed appropriate or not.

Based on the example above, it is clear that compression didn’t jump to 45% overnight, nor is it likely that it increased steadily over time. In the example, it appears that the schedule became compressed starting in August 2015. This narrows down the period of time which compression needs to be investigated.

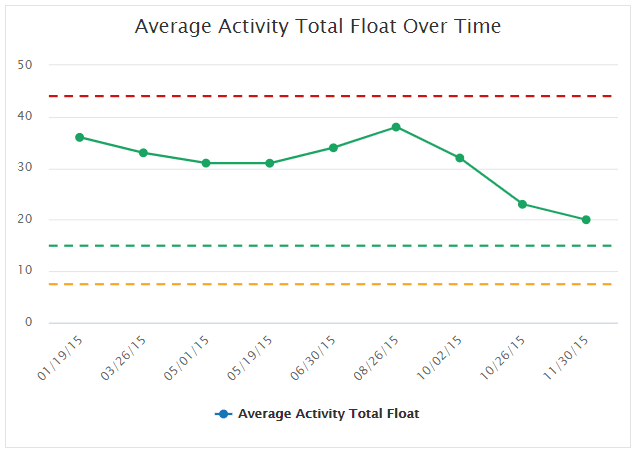

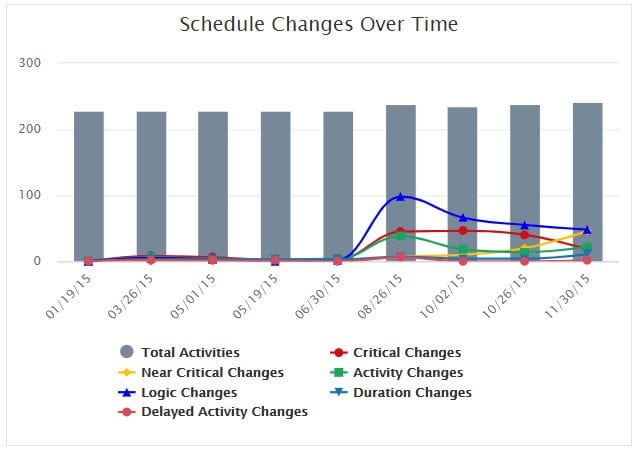

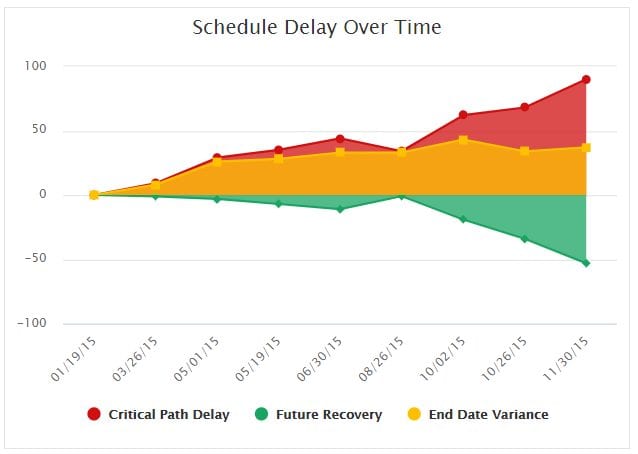

Additional analyses can be performed with schedule data to better identify the reason compression exists. Such analyses include an analysis of schedule changes over time, average total float over time, and an analysis of delay and recovery over time. See examples below.

An analysis of average total float decreasing over time indicates that total float is being consumed, indicating that work is continually being pushed off.

In addition, the extent of changes appears to be occurring in sync with the increases of compression indicating that some of the compression is a result of the changes made to the schedule.

This correlation can be further verified by the critical path delay increasing over time as the end date variance remains constant in the periods where changes occurred.

At this point, given the situation, the next step would be to bring the schedule to an acceptable level of compressions by rejecting many (if not all) historical changes to the schedule updates starting with the update on 8/26/2015.

Again, given the challenges presented by the pandemic, it is in all stakeholder’s best interests to analyze schedule compression, and to confirm that there aren’t any unachievable and overly compressed project schedules as we enter into the next year of potential COVID-19 impacts.

The SmartPM team is happy to assist in the process of calculating and understanding compression using the SmartPM schedule analytics technology.

* It is recommended that the plan versus actual progress curves be generated using a resource or cost loaded project schedule. If the schedule is not resource loaded, a model should be developed that factors in weighted averages based on activity durations as a means to estimated planned versus actual progress.

Leave a Reply