— 10 min read

Understanding and Managing Construction Labor Costs

Last Updated Aug 13, 2024

Last Updated Aug 13, 2024

Construction labor costs represent a huge portion of total construction expenses on a project — up to 50-60% of total costs for some project and contract types.

Labor costs go far beyond wages, from training and onboarding to paid time off, benefits and payroll taxes. The magnitude of labor costs gets more complicated when accounting for the construction labor shortage and its impact on competition for construction talent.

This article will discuss all the different elements of labor costs on construction projects and how to use labor resources effectively.

Table of contents

Self-Performing or Hiring Subcontractors

Contractors may follow one of two general paths when it comes to their labor force. Self-performing contractors take on a project and intend to do much of the work themselves, while typical general contractors typically take on a project and subcontract some or all of the specialty trades work to other contractors. Self-performing contractors will realize a much larger labor expense than GCs who outsource most of their work to subcontractors.

Labor costs will vary a great deal from one job to another. Contractors experienced with self-perform projects develop a keen sense of how much labor will cost on any given project — it's their lifeblood to ensure that they are making a profit on that particular project, and a great deal of that is controlling labor costs.

Comprehensive records of past builds can help self-performing contractors estimate the time it will take to complete specific tasks. Using reliable previous project data, they can simply multiply the time required by current labor costs for that type of work to arrive at a labor cost for a project.

While labor costs have increased over the years, the proportion of construction expenses they represent has remained fairly stable – as wages increase, overhead and materials costs also increase.

Understanding Construction Labor Costs

Employees cost contractors far more than just the total wages or salaries they receive. Keeping employees on staff involves many other expenses:

Wages and Salaries

Construction employees' wages vary by region and whether or not they are unionized. Unions negotiate labor rates for large chunks of time, so their rates will stay predictable — and predictably higher — than those of non-union labor.

The wages of non-union labor and skilled trades workers can vary greatly based on supply and demand. If a new project is located in an area where competition for construction labor is high, labor costs may be quite high.

Learn more: Guide to Working With Construction Union Labor

A 2023 update to the Davis-Bacon and Related Acts ruled that workers on projects under federally funded or assisted contracts should be paid "no less than the locally prevailing wages and fringe benefits for corresponding work on similar projects in the area."

Workers who possess specialty skills tend to be costlier to hire than the average laborer. Construction firms should research these variables to see how they'll impact labor costs before bidding on a project.

Benefits and Allowances

The benefits that apply to construction workers can vary a great deal from one employer to another, although the federal government has set some minimum requirements for employers across the country.

For instance, workers in the US are entitled to overtime pay (at a rate of at least 1.5 times the regular rate) if they work more than 40 hours in a week. The Patient Protection and Affordable Care Act (PPACA) requires employers with more than 50 employees to offer health coverage to full-time employees.

Benefits may or may not apply to non-union labor, although they can be an incentive to attract workers in competitive labor markets. To maintain a consistent, reliable workforce, contractors often hire the same laborers and skilled contractors from one project to another. Contractors can show their appreciation for these valuable repeat employees by offering health benefits and 401(k) plans for employees who've been with them for an extended time or who have proven their worth to the company.

Pro Tip

Why Would GCs Hire Union Labor?

Union labor generally represents higher labor costs for contractors, but union labor may be required on some projects, including those that are publicly funded. Labor costs for union workers include health insurance, retirement plans, and paid time off.

Hiring union workers has some direct benefits to project work. Unions often have stringent training requirements for members' craftsmanship and safety, include the most experienced and skilled workers in the field, and are great for contractors' public relations. Still, if union labor isn't required, a contractor will usually hire a non-union contractor with a solid reputation for good work.

In some situations, a contractor may hire a union worker even if not required to do so. A contractor who is very familiar with a union foreman or superintendent from previous jobs may decide to work with that person even on a non-union job. These arrangements go against union rules, however, and neither contractors nor laborers would attempt this in a place like New York City, where unions are powerful.

Taxes

Businesses are responsible for paying a matching share of employees' Social Security and Medicare taxes, as well as unemployment taxes for each person on the payroll. The medicare tax rate is 1.45% of total wages (2.9% total), while the social security tax is 6.2% (12.4% total). Unemployment taxes are run through a joint effort between the federal and state governments, so amounts may vary by state.

There are also administrative costs of calculating, withholding, tracking, and submitting the correct taxes for all employees. Employers submit employment taxes quarterly, while unemployment taxes are reported annually.

Overtime Pay

Construction projects are often heavily time-driven. Contracting teams who fail to meet predetermined milestones and deadlines may face huge financial penalties that could reach $10,000 a day or more. Rather than face these extra costs, contractors may choose to have employees work overtime, which itself can get very costly. Workers who work more than eight hours at a time, weekend shifts, or off-shifts may be entitled to time-and-a-half or double-time wages.

Training and Education

Not all contractors offer their employees opportunities to develop through ongoing training courses.

There's good reason to delay (or even skip) educational opportunities. Training isn't cheap. Training requires workers to spend time and billable hours in a classroom instead of a job site, and training programs may use expensive materials or third-party educators.

However, ongoing training can help construction employees become safer, more productive, and more competent with technology, each of which can increase profits over time. Training can improve employee satisfaction and loyalty, too.

Take safety training as an example: Workplace injuries account for 6-9% of project costs, but good health and safety training accounts for just 2.5% of project costs.

Courses about construction.

For construction.

Unlock your career potential with our free educational courses on Health & Safety, Data in Construction, and more.

Calculating Total Labor Costs

Some contracting companies estimate labor costs consistently across projects; those are usually the companies with rich data stores that can provide past information to work from. For instance, they’ll know how many hours it took to pour a certain amount of concrete or to lay a specific length of pipe.

Historical records only tell some of the story, though. The strength in experience comes when the GC knows which project variables will take more or less time. Laying pipe in tough or rocky terrain will inevitably take up more labor hours than in easier soil. Using that information, the contractor can multiply the number of labor hours by the current labor rates to estimate total labor costs for that section of work.

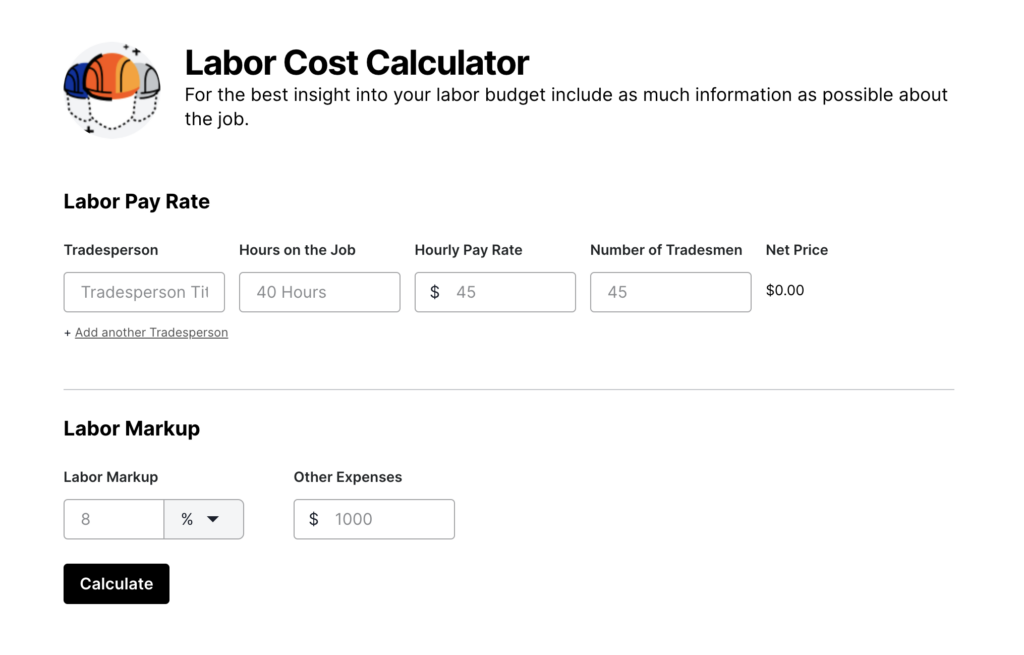

Want to estimate labor costs quickly? Try the free Labor Cost Calculator. Just add basic employee information and quickly calculate the total cost of labor for any project.

Managing Construction Labor Costs

Like most construction project expenses, contractors can manage labor costs with accurate tracking, analysis, and planning.

Make Efficiency a Priority

Managing any workplace expense means making the most of what's available. A contractor lucky enough to have a full roster of workers should ensure those workers are working as efficiently as possible.

A solid workforce management strategy can save a lot of frustration and downtime. Workers should be scheduled for the right job at the right time, doing work that fits their skill sets. Good employee management software can help get everyone at the right place at the right time.

Construction management software can help detangle communications between stakeholders so that work gets done right the first time to minimize rework. Reducing rework helps to minimize costs for labor, materials, equipment rentals, and any fines related to schedule delays.

Safety Matters

Keeping workers safe is not only the ethical thing to do, it's also good for the bottom line. A single lost-time injury costs a contractor disrupted work schedules, all costs related to replacing the worker, as well as a hit to the business reputation, and any resulting litigation fees.

A focus on health and safety training may contribute to employees' sense of job satisfaction and how they feel they're valued at work.

Courses about construction.

For construction.

Unlock your career potential with our free educational courses on Health & Safety, Data in Construction, and more.

Inventory Management

Effective inventory management helps to manage labor costs by keeping site crews on the job and working productively. Often, when materials aren't available as needed employees need to head to the hardware store to purchase the missing items, which is an ineffective use of their time.

Project progress may even stall as employees wait for the required equipment or materials to arrive. Imagine arriving at a site on a day that concrete needs to be poured, but there's no concrete truck or the required tools aren't present. That creates a lot of downtime and could push out the schedule, which can be extremely expensive.

Price with a Buffer

Preconstruction efforts can go a long way in avoiding unexpected delays on site, but sometimes there are still surprises. Elements like weather and ground conditions can hamper progress and create new costs.

Change orders can help to offset some added costs and schedule delays, but when the team has to reach a project deadline, they may wind up working overtime and incurring overtime pay. It's a good idea to include a buffer in project bids in case of unknown project conditions because it's impossible to know for sure what the project will cost to the contractor ahead of time.

Pro Tip

Balancing Deadlines and Overtime Costs

Labor costs are always important for self-perform contractors, but they’re not always the most important element on a project. On some projects, the deadline — and the penalties for not meeting a deadline — takes over, and the general contractor decides to spend whatever it takes to finish the job on time.

When that happens, there may be workers onsite at all hours, pulling in very high hourly rates, because it would cost more to pay for working beyond the deadline.

Labor cost and scheduling pressures are a balancing act, and the balance may look different from project to project.

Using Labor Well

Construction costs include the wages each worker earns and the costs of supporting that employment with benefits, training, and taxes. Put together, all the expenses involved in hiring staff can represent around half of project expenses.

Contractors can help to manage these costs by planning ahead to identify as well as possible what labor costs will be for a project, using technology to ensure workers are assigned to work that best uses their skills and abilities and to ensure good inventory management to keep work crews busy on site. Finally, construction companies should consider leaving a buffer in their estimates to cover extra labor costs that come up when unexpected situations arise.

Without labor, construction doesn't happen. Working to attract and retain employees, and use current employees efficiently, can help manage labor costs on construction projects.

Was this article helpful?

Thank you for your submission.

67%

33%

You voted that this article was . Was this a mistake? If so, change your vote here.

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Categories:

Tags:

Written by

Ryan O'Donnell

Ryan O'Donnell works at Procore as Senior Product Manager, Financials. He has spent his career working in construction finance -- including roles as Controller & CFO for Terminal Construction Corporation in NYC, AVP of Commercial Real Estate at M&T Bank, and Senior Auditor for Kiewit Infrastructure Group. Ryan earned his MBA in Accounting & Finance from Rutgers University. He lives in New York.

View profileKristen Frisa

67 articles

Kristen Frisa is a contributing writer for Procore. She also contributes to a variety of industry publications as a freelance writer focused on finance and construction technology. Kristen holds a Bachelor of Arts in Philosophy and History from Western University, with a post-graduate certificate in journalism from Sheridan College. She lives in Ontario, Canada.

View profileExplore more helpful resources

Modular Construction and MEP: A Collaborative Pairing

In an age of supply chain disruptions, workforce shortages, and rising material costs, off-site construction — including modular construction methods and prefabricated materials — is surfacing as a multipurpose solution....

Connected Construction: Transforming the Industry Through Integration

Construction projects are becoming increasingly complex, so companies need to innovate to accurately and profitably complete these modern structures. Connected construction — using technology and data to improve communication, processes...

Off-Site Construction: Prefab vs. Modular

As the construction world becomes ever more competitive, deadlines get tighter and the margin for error gets slimmer, project owners around the world are always looking for an edge. Thanks...

The Role of BIM in Sustainable Construction

Building information modeling (BIM) is transforming the architecture, engineering, and construction (AEC) industry. With this kind of sophisticated modeling, the industry has shifted from designing in 2D to 3D. This helps...