— 7 min read

Forensic Schedule Analysis: Unlocking Insight Into Project Delays

Last Updated May 30, 2025

Justin Vogel

Senior Solutions Engineer, Owners

Justin is a Senior Strategic Product Consultant for Procore. Justin has an extensive background in real estate development, construction engineering, and project management professional entrusted with high profile structures, and is involved in over $3.5 billion worth of construction representing developers, CEO's, GC's, equity partners, consultants, and attorneys in unique and complex pursuits.

Kristen Frisa

Contributing Writer

113 articles

Kristen Frisa is a contributing writer for Procore. She also contributes to a variety of industry publications as a freelance writer focused on finance and construction technology. Kristen holds a Bachelor of Arts in Philosophy and History from Western University, with a post-graduate certificate in journalism from Sheridan College. She lives in Ontario, Canada.

Last Updated May 30, 2025

Though construction sites may sometimes look like a large collection of machines, ultimately, it’s people who get things built. However, people aren’t perfect, and delays happen all the time — which costs time and money. But who is responsible for paying for those mistakes? A forensic schedule analysis can answer.

Forensic schedule analysis is the process of pinpointing where and why delays happen during a project. This detailed review often involves legal steps as companies seek to hold others accountable for any added costs caused by these delays. Sometimes, an analysis is even performed more casually to help a company refine its processes and prevent future problems.

This article will explore the triggers of a forensic schedule analysis and the steps involved in the process.

Table of contents

What makes up a construction schedule?

In the context of a forensic schedule analysis, the “schedule” refers to the project or construction schedule, a published document that uses the critical path method (CPM) that lists the critical events, activities and milestones on a project. The schedule dictates what needs to be done in order to deliver the project on time.

Contract documents that the owner presents to the contractor include a project schedule called a baseline schedule which dictates the start date and the date the project should be completed to meet substantial completion. The contractor creates a schedule for each activity that fits into those two dates.

But when managing construction projects, it's common for errors to cause schedule delays, extending the project timeline. A forensic delay analysis would take place when delays are great enough — or the consequences dire enough — that the owner or the contractor needs to make up the lost time or revenue.

What happens when a project schedule is delayed?

As a construction project progresses, updated schedules allow the project team to gauge how well it fits into the project schedule. When updated schedules show that the project is behind, and likely to miss contractual completion dates, it becomes the GC’s job to get it back on track.

For example, if a contractor is responsible for a concrete pour but the finished concrete doesn't meet the compression test and has to be ripped out and completed again, the contractor will be responsible for doing whatever they can to catch up to that schedule.

Some solutions the contractor might use to make up time are to work weekends, work overtime, overlap activities, or allocate more staff to speed up project progress. If none of that feels like it will be enough to get things back on track, or if the contractor wasn’t the one who caused the delay, the contractor may approach the owner about approving a change order to allow for more time to complete the project.

The Purpose of a Forensic Schedule Analysis

Delays cost money — so who's responsible for paying? If the contractor or the owner feels the delay is someone's fault — even if there were also outside circumstances that contributed to the problem — that's when lawyers get involved.

Part of the difficulty of conducting forensic delay analysis is that none of this happens in a vacuum. While these decisions are being made, there are still crews on site, construction is still happening.

When any of the parties seeks damages it will be because of damage to a business or a bottom line. For example, if the GC is no longer profitable, if the company will no longer earn money on a project they consider if it's even worth their time to finish the job or if the losses are likely to grow.

Owners look at whether the delay in project completion has cost money or reputation. For instance, if the project is a casino, it is bound to produce income for the owner when its doors open. Any delay in the substantial completion date will cost the owner revenue. The delay analysis will seek to assign blame to recoup some of those losses.

How to Complete a Forensic Delay Analysis

A forensic delay analysis may occur during or after a project. During a project, if an updated schedule shows that final milestones are slipping outside the contractual delivery substantial completion date, that's when a forensic analysis will begin.

The first step of a forensic delay analysis is to look closely at the time it took to complete the project compared to the contractual completion date. This process starts with a schedule index.

Schedule Index

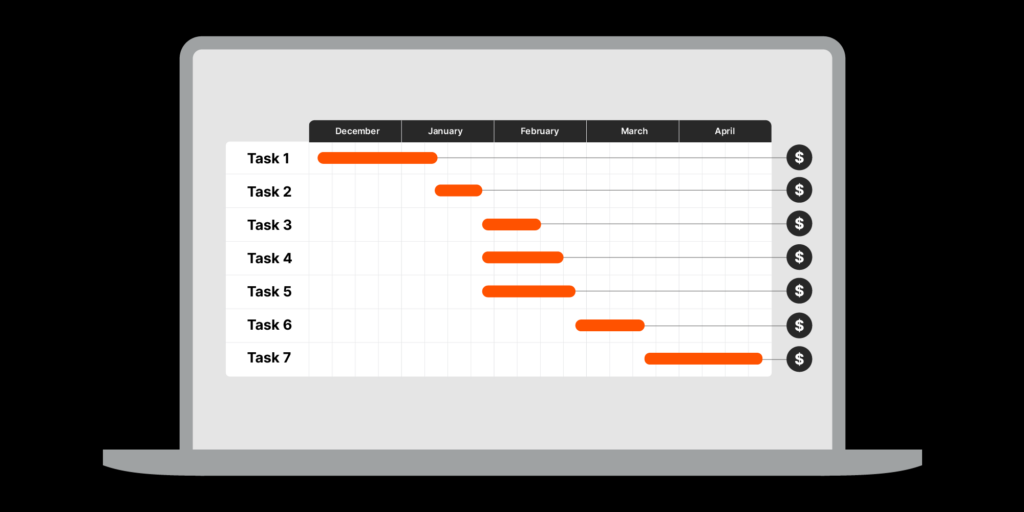

A schedule index consists of a table that goes down the page, listing each of the schedules that were issued for the project. It starts with the baseline schedule, then moves on to the monthly schedule update that is produced as part of the contractor's pay app. Going across, the table will list all of the critical milestones tracked as part of the project.

The schedule index will offer a picture of how the schedule developed compared to the contract throughout the project. The process will examine what each team member knew at each point in the project, to identify the points that the project deviated from the original schedule. Keep in mind, contract dates might change throughout the schedule index, but only where change orders have been executed at those points in time.

Window Analysis

Next, the team conducts a window analysis. Instead of examining all of the schedules, they isolate where the projected milestone completions changed, trying to figure out the story behind each and why it changed.

Following the Evidence

At the end of the analysis, the project team should have a good idea of what happened and what should have happened, and be able to make conclusions about improving the processes going forward. The process may also seek to assign blame for any delays so that any financial repercussions will be properly allocated.

A forensic delay analysis can take considerable time. The process involves reviewing change orders and documents one after another. When they don't line up, that's where the evidence can lead to the source of the delay.

It's much more straightforward to conduct a forensic schedule analysis when all of the documents, directives, and conversations for a project are all in one place.

Managing the Outcomes of a Forensic Delay Analysis

Delays are a common cause of disputes within the construction industry. However, some best practices can help prevent them from leading to long legal battles.

Have a plan in place.

Every project should have a set process in place that dictates what to do when the project falls behind its schedule. When the change arises and the delay follows, a change order process should kick in so that the GC and the owner both know what happens next.

Force a decision.

Change orders can lead to disputes when an owner neglects to either approve or deny it, leaving the contractor and project hung up waiting for an answer. This can happen when the owner doesn't want to approve a big charge, or just isn't sure about what they're being asked to approve.

Having predetermined processes in place can help the owner make a decision quickly. Keeping documents and communications open to all parties can help keep owners in the loop even if they don't understand every nuance of the project.

Communicate.

Open communication between stakeholders can help everyone make good decisions about their actions in the moment. A broad understanding of all project information can also inform each stakeholder's decisions so they understand the far-reaching impacts of those decisions. Putting the schedule in a shared location where everyone can access it can help put everyone on track toward a shared goal.

If all stakeholders, even trade partners, vendors and architects are privy to the same information, it's less likely that the project will find itself in these spots where one person drops the ball that impacts everyone else.

Broader Uses for Forensic Schedule Analyses

The temptation is to only look at problematic projects in order to discern what went wrong and make plans to do better next time. However, there's a case to be made for performing forensic schedule analyses on some of the projects that turned out well, too. There are valuable lessons available in past project data.

Going over past projects to see what went right and wrong can lead to continuous improvement. Construction is won and lost in profit margins, so understanding what’s working and what’s not can be the crutch that keeps a company from going under.

Was this article helpful?

Thank you for your submission.

67%

33%

You voted that this article was . Was this a mistake? If so, change your vote

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Thank you!

You’re signed up to receive The Blueprint newsletter from Procore. You can unsubscribe at any time.

Categories:

Written by

Justin Vogel

Senior Solutions Engineer, Owners | Procore

Justin is a Senior Strategic Product Consultant for Procore. Justin has an extensive background in real estate development, construction engineering, and project management professional entrusted with high profile structures, and is involved in over $3.5 billion worth of construction representing developers, CEO's, GC's, equity partners, consultants, and attorneys in unique and complex pursuits.

View profile

Kristen Frisa

Contributing Writer | Procore

113 articles

Kristen Frisa is a contributing writer for Procore. She also contributes to a variety of industry publications as a freelance writer focused on finance and construction technology. Kristen holds a Bachelor of Arts in Philosophy and History from Western University, with a post-graduate certificate in journalism from Sheridan College. She lives in Ontario, Canada.

View profileExplore more helpful resources

Mastering Construction Resource Management: Strategies for Success

Completing construction projects successfully requires the careful management of various resources: labor, materials, equipment, money, time and information. Since these resources are finite, allocating them wisely is crucial for minimizing...

Cost-Loaded Construction Schedule: Analysis, Risks & Benefits

Both scheduling and cost control are make-or-break aspects of construction projects, but in many cases the two areas are kept very separate from one another — the project scheduler and...

Understanding the Last Planner System in Construction

Construction scheduling is a complex process affecting multiple stakeholders. Increasing accuracy and collaboration with trade partners when scheduling construction work can positively impact on-site workflow and efficiency. The last planner...

Mastering the Critical Path: A Guide to CPM in Construction

While every task must be completed to complete a construction project, some tasks are more critical than others. It’s crucial to be able to identify which activities must be finished...

Free Tools

Calculators

Use our calculators to estimate the cost of construction materials for your next project.

Templates

Find a template to help you with your construction project tasks.

Material Price Tracker

Get the latest U.S. retail prices and view historical trends for common building materials.

Glossary

Explore key terms and phrases used in the industry.