— 7 min read

Understanding the Types of Road Construction Equipment

Last Updated Jan 29, 2025

Last Updated Jan 29, 2025

Although roadway construction may appear straightforward, it involves precise engineering and processes that require specialized equipment beyond that typically used for other projects. This article will explore the various types of paving and road-building equipment, their uses and how to choose and manage this equipment.

Table of contents

Choosing and Managing Road Construction Equipment

Road building projects vary in type and size, so choosing the right equipment can save time and money. Companies can flexibly expand their road construction equipment with rentals as business in this specialized trade fluctuates or increases. Rentals also provide a way to field-test equipment to determine what works best before purchasing.

To determine the appropriate equipment, consider the features, power and capacity in relation to the size and scope of upcoming projects. Many pieces of equipment can be fitted with attachments, so standard construction machines with specialized accessories can be used in roadway construction to save costs. However, paving generally requires machinery explicitly designed for that function.

Construction management software offers planning and resource management modules that help track road construction equipment needs, placement and the workers required to operate it. Whether rental or company-owned roadway equipment, a central and accessible software solution can help contractors schedule work and equipment efficiently and cost-effectively.

Construction Equipment Commonly Used in Roadway Construction

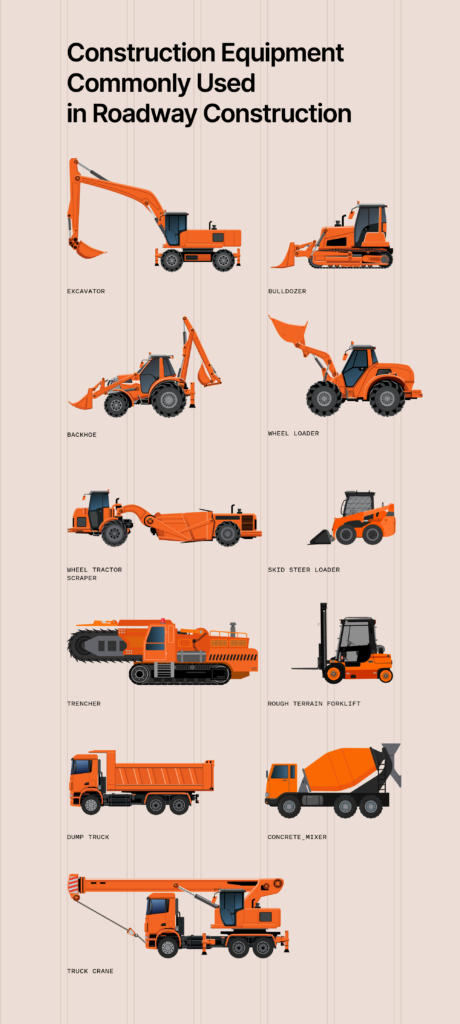

Road construction also uses standard construction equipment for various tasks. The following machines are used on many types of construction projects but have integral functions in roadway building.

Excavators

Excavators are versatile heavy construction equipment used primarily for digging and removing earth and rocks. They are also sometimes used for heavy lifting, hauling, demolition and clearing brush.

Bulldozers

Bulldozers are used for soil excavation and to push weak soil or rock strata to level the road area.

Backhoes

Backhoes are versatile tools for excavating, loading materials, breaking up asphalt, digging up trees and minor demolition.

Wheel Tractor Scrapers

Wheel tractor scrapers are used to level surfaces and have a sharp blade and conveyor belt to collect material. They can spread or remove large amounts of material and increase efficiency.

Wheel Loaders

Wheel loaders move soil, rock and other materials around the roadway site, depositing larger loads into dump trucks.

Trenchers

Trenchers — as the name suggests — dig trenches for cables or pipes, and they can also dig trenches for drainage of roadways. Because road builders often have to work closely with utility structures, trenchers are common on road projects.

Dump Trucks

Dump trucks move demolition debris, soil, rocks and other materials around the site and remove them from the area.

Concrete Mixers

Concrete mixers are used in roadway construction to mix cement, water and aggregate to form roadways, sidewalks and curbs.

Truck Cranes

Truck cranes are used in road building to lift and move concrete barriers, signage and other infrastructure. They can also position heavy construction equipment such as pavers and rollers.

Pile Drivers

Pile drivers help create stable foundations for roadways and bridges by driving piles into the ground to support heavy loads and withstand environmental challenges.

Skid Steer Loaders

Skid steer loaders are versatile machines that can be fitted with attachments for demolition, grading and paving in roadbuilding projects.

Rough Terrain Forklifts

Forklifts move heavy materials around a site, and rough terrain forklifts are especially useful on road construction sites to move materials or equipment on uneven surfaces.

Specialized Road Building Equipment

The following types of equipment have specific roles in road construction, though they may also serve needs for other building projects.

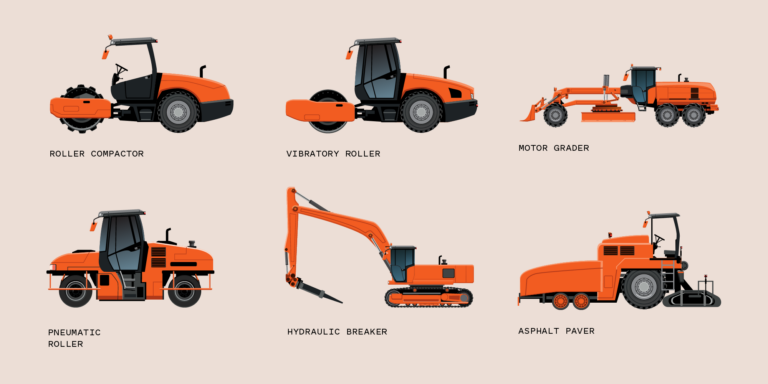

Compactors/Rollers

Soil compactors are used to compact dirt to prepare for laying the roadway. Various other types of rollers are used to compact gravel, crushed rock and sand. Pneumatic tire compactors, rubber tire rollers and vibratory rollers are the types most suited to smoothing asphalt.

Hydraulic Breakers

Hydraulic breakers are attachments to excavators that break up concrete or asphalt for demolition. They are sometimes called percussion hammers and can also break up rocks or large obstacles.

Road Reclaimers

Road reclaimers pulverize the existing asphalt layer and mix it with the underlying base to create a stable, rejuvenated roadway. Sometimes, asphalt binders, emulsions or cement are added to the mix.

Motor Graders

Motor graders — also called road graders — are used for leveling surfaces. They have a blade between the front and rear wheels that is lowered to flatten the soil surface.

Asphalt Pavers

Asphalt pavers, also called asphalt finishers, distribute the asphalt layer evenly and provide initial compaction. Dump trucks continuously load asphalt to the hopper of the paver, where it is then moved by a conveyor belt, spread onto the roadway and flattened.

Remixing Transfer Vehicles

Remixing transfer vehicles are sometimes used to actively remix asphalt between the dump truck and the paver for temperature uniformity. This creates a smoother and more consistent roadway surface.

Cold Planers

Sometimes also called milling machines, cold planers are designed to remove the top layer of asphalt or concrete to create a level, textured roadway surface. The roadway can be opened to traffic before a new asphalt layer is applied.

Slipform Pavers

Slipform pavers continuously mold concrete through extrusion to form curbs, gutters, medians, barriers and roadways. They create neat, uniform structures and can reduce the need for manual labor.

Chip Spreaders

Chip spreaders distribute a layer of gravel or crushed stone over a freshly applied layer of asphalt or tar to create a chip seal surface, providing skid resistance and waterproofing.

Tack Distributors

Tack distributors, also called tack trailers, spread a thin layer of asphalt emulsion to bind old and new road surfaces together to make road surfaces more durable.

Shoulder Spreaders

Shoulder spreaders are usually attached to a loader, skid steer or grader and used to distribute and grade asphalt or aggregate on the shoulder of a roadway.

Line Striping Machines

Line striping machines apply paint for traffic direction, parking lot lines and other pavement markings.

Asphalt Plants

For large projects, an on-site asphalt plant can mix and heat asphalt, aggregates and additives precisely for the type of blacktop needed.

The Road Construction Process Simplified

After planning and preconstruction, the active phases of road construction can begin; this is where road-building equipment comes into play. Here is a summary of the process.

Site Preparation

Before digging and leveling the surface for a roadway, vegetation, debris and any other obstructions must be cleared from the site. Earthworks and excavation then shape the level surface to place the roadway.

Aggregate Placement

Next is creating a stable base for the road. Aggregate, which consists of crushed stone or gravel, is placed on top of the leveled subgrade and compacted to ensure road stability.

Paving and Drainage

Placing the top layer of the road requires making the correct mixture of concrete or asphalt and then laying and smoothing the pavement. Proper drainage makes roadways safe to drive on, so placing gutters, curbs and storm drains can direct water away from the road.

Additional steps may include lighting, signage, sidewalks and markings. Each step requires a mix of equipment types, and the specifications of the project roadway will help determine the number and capacity of equipment appropriate to complete the work.

Effective site logistics help manage the movement and placement of equipment during the build to support a safe and productive working environment.

Courses about construction.

For construction.

Unlock your career potential with our free educational courses on Health & Safety, Data in Construction, and more.

Advancements in Road Construction Equipment and Processes

Automation promises to increase productivity and accuracy while reducing costs and time in road construction. Geolocation and digital models may soon help automate more road construction equipment and make managing and overseeing the construction process more efficient. With GPS, machinery can operate in precise locations to construct roadways and other infrastructure accurately.

Advancements in semi-autonomous equipment can allow one operator to control multiple machines, requiring fewer workers and decreasing site risk and expense. Prototypes are being tested, but labor shortages in the industry may compel wider adoption of this technology in the near future.

Digitization and analytics are poised to impact road design and construction. Sensors can monitor traffic and roadway conditions for predictive maintenance. In addition, software platforms incorporating AI are shifting the construction process toward greater efficiency, upending traditional workflows. Advanced materials like plastic can improve road strength but may require changes in the equipment and process used to lay down roads.

Understanding the array of equipment used in road construction can be valuable for companies looking to expand their capabilities or collaborate effectively on projects involving roadways. With the high demand for new and upgraded infrastructure, particularly roads and bridges, efficient site management can improve productivity in roadway construction.

Was this article helpful?

Thank you for your submission.

100%

0%

You voted that this article was . Was this a mistake? If so, change your vote here.

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Categories:

Tags:

Written by

Julia Tell

45 articles

Julia Tell is a freelance writer covering education, construction, healthcare, and digital transformation. She holds a Ph.D. in Media & Communications and has written for publications including Business Insider, GoodRx, and EdSurge, as well as nonprofits, international businesses, and educational institutions.

View profileExplore more helpful resources

Tackling the Top 10 Construction Industry Issues

The construction industry is constantly evolving, bringing both opportunities and challenges. Companies must navigate an array of construction industry issues — from workforce shortages to integrating new technologies into their...

Mission Critical Construction: Strategies for Success

Mission critical construction involves building structures whose functions cannot afford to fail, as any disruptions can lead to significant consequences for society. Keeping data centers, hospitals, power plants and other...

Modular Construction and MEP: A Collaborative Pairing

In an age of supply chain disruptions, workforce shortages, and rising material costs, off-site construction — including modular construction methods and prefabricated materials — is surfacing as a multipurpose solution....

Connected Construction: Transforming the Industry Through Integration

Construction projects are becoming increasingly complex, so companies need to innovate to accurately and profitably complete these modern structures. Connected construction — using technology and data to improve communication, processes...