— 8 min read

Navigating the Challenges of Underwater Construction

Last Updated Feb 5, 2025

Last Updated Feb 5, 2025

Underwater construction underpins many aspects of modern infrastructure — from anchoring bridges and securing ports to running cables and pipelines across bodies of water — integrating human civilization with aquatic environments.

This article explores the applications, methods and materials needed for underwater construction — plus some of the technological advancements that are enhancing safety, strength and adaptability in this process.

Table of contents

Uses for Underwater Construction

Structures under waterways are integral to contemporary life. There are tunnels and bridges regularly traversed by people and freight, offshore energy production to power cities and towns, cables that drive global communications and ports that keep goods moving to fuel our economies. While the above-ground features are more familiar, many important structures would not be possible without the underwater foundations that support them.

Beyond necessary infrastructure, hospitality companies are building underwater hotels and restaurants, with the excitement of viewing ocean life as a unique attraction in the tourism industry. Projects like this are operational in Norway, Dubai, China, the United States and the Maldives, with additional projects in the pipeline. Skyscrapers with foundations extending below the land surface are also being built, offering communities ways to position buildings in coastal areas.

Here are some applications for underwater construction:

- Harbors, piers, seawalls, docks and jetties

- Wind turbines and tidal power generation facilities

- Power and fiber optic cables

- Submarine gas and water pipelines

- Dams, reservoirs and canals

- Hydroelectric plants

- Power station cooling and industrial wastewater systems

- Artificial reefs, research facilities and aquariums

- Hotels, restaurants and museums

Rising water levels make building strong and safe infrastructure near and in waterways increasingly necessary. Many societies need underwater infrastructure, and unique construction techniques make that possible.

Tackling the Challenges of Building Underwater

Underwater construction projects are risky, expensive and logistically complex. Many civil and commercial construction projects have some aspects that require underwater work, so general contractors will likely need to partner with trade specialists for the more specialized tasks associated with building in wet environments. Here are some of the difficulties associated with building under waterways:

Work Environment

Water pressure, poor visibility and temperature variations can make building challenging and unpredictable. Construction techniques must accommodate the specific water pressure of the build's depth, and specialized tools and safety equipment are necessary. Darkness or muddy water can make it difficult to see the project. Variable temperatures can change how materials respond, and wave conditions may necessitate schedule changes. Well-coordinated project management can help handle the dynamic nature of this work.

Material Selection

Underwater construction materials must resist corrosion, withstand water pressure and be designed to cure and set underwater. Concrete, steel, acrylic glass and fiberglass-reinforced plastic are some of the materials used. Specialized concrete mixtures and composite materials are needed for many projects, requiring careful planning for sourcing or mixing.

Worker Training and Safety

Skilled labor is required for underwater projects like welding, cutting, operating specialized equipment and diving. Workers must be physically fit and able to swim to maneuver and position themselves and their equipment in water, as well as have training and certification in these skills.

Unpredictable water conditions and the possibility of entrapment or decompression sickness exacerbate safety risks. A robust safety plan, a strong safety culture and meticulous equipment maintenance can mitigate these risks.

High Costs and Staying On Budget

Specialized equipment and materials, a highly skilled workforce and hazardous work environments entail higher costs and greater financial risks. Getting equipment and workers to inaccessible sites also increases costs.

The high costs of underwater infrastructure projects often necessitate financing as public-private partnerships. Project management software can help track resources and budgets, support communication for collaboration between teams and assist in planning complex work in unpredictable environments to lower the risk of cost overruns.

Environmental and Regulatory Complications

Underwater construction risks disturbing ecosystems and polluting water systems. Noise pollution, dredging and pollution from discarded materials can harm aquatic life. Projects must commission environmental assessments (EAs), which follow applicable regulations set forth by the Environmental Protection Agency (EPA), which could include international maritime law, state or federal environmental regulations and local municipality requirements. Navigating the complex permitting and legal aspects of underwater projects often requires hiring consultants and keeping teams apprised of inspection and documentation requirements to keep the project on schedule.

Construction Techniques for Underwater Structures

Creating structures underwater often requires unique methods of keeping water away as they are placed or built. Though the final structure will need to withstand a water environment, constructing in dry environments is more practical for materials to cure properly and for safer working conditions.

Though some techniques, such as caissons, have been used since the Roman era, updates and new ideas are continuously improving processes.

Caissons

Caissons are hollow structures that keep water out while construction is completed underwater. They can be rectangular or circular and usually remain on site as part of the foundation of the newly built structure. The caisson is lowered into the water to the specified depth, and concrete is poured to provide a stable, load-bearing foundation.

There are three basic types of caissons.

Box Cassion

Box caissons have a floor but an open top that extends above the water. They are sunk to the bottom, anchored in position and filled with concrete.

Open Caisson

Open caissons have no floor or top but a cutting edge at the bottom that helps them sink through softer ground to reach the desired depth. Excavation can occur inside until the structure is ready for a concrete foundation to be poured.

Pneumatic Caisson

Pneumatic caissons have no bottom but are sealed at the top and filled with pressurized air to keep water and sediment out. Workers inside, typically called “sandhogs,” clear out mud and debris until the structure is at the correct depth, then exit the chamber and fill it with concrete.

Cofferdams

Cofferdams are temporary structures used to keep water out during construction work. The temporary enclosure of a cofferdam allows water to be pumped out so work can proceed in a dry environment. Common materials used to make cofferdams include steel sheet piles, soil and rocks.

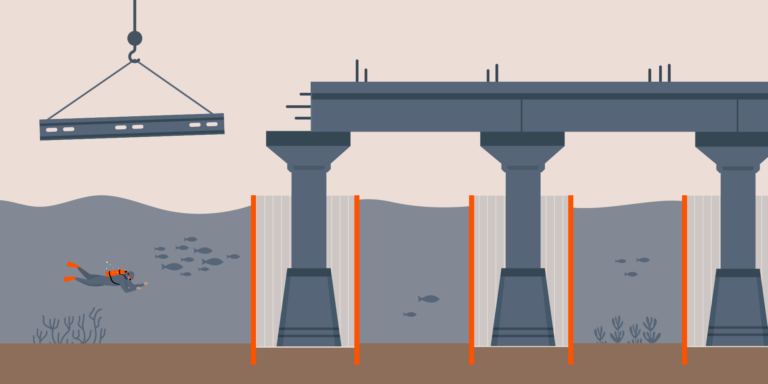

Driven Piles

Driven piles are deep foundational structures created by pounding steel tubes into the soil and filling them with concrete. A hydraulic hammer repeatedly strikes the pile until it is deeply embedded in the ocean floor; then, as concrete is poured in, the water is displaced. Driven piles create a very solid and cost-effective foundation for underwater construction.

Off-site Building

Structures are often built off-site and transported — or floated — to the site by barge, where they are lowered. The pre-built structures are often modular and attached to driven piles in the waterbed to minimize risks and time spent performing underwater construction processes.

Underwater Welding

Considered one of the most dangerous jobs, underwater welders need an understanding of arc-welding, diving and safety protocols to perform this work in hyperbaric (or pressurized) environments. Wet welding is performed directly in the water, while dry welding occurs in a pressurized chamber. The risks include electrical shock and decompression sickness, and workers need to have diving certification and welding or metal fabrication training.

Driving Efficiency with Technology in Underwater Construction

Safely building affordable and durable underwater structures can push the boundaries of innovation and benefit from the latest technological advancements. With constantly improving materials and machinery, underwater construction can help support society’s needs into the future. Here are some of the advancements that are improving outcomes for underwater projects:

Combining Time-tested and Advanced Materials

Concrete and steel are age-old construction materials integral to underwater construction, but cutting-edge admixtures, composites and coatings can help lessen the effects of water environments on these materials. High-density polyethylene and geopolymers containing fly ash or slag, along with acrylics, are increasingly useful for underwater applications.

Aluminum and titanium are corrosion-resistant, with titanium especially strong for deep-sea structures. Polymer and epoxy resins help bind concrete and can be used in coatings.

Using Robotic Submersible Equipment

To mitigate some risks to workers, remotely operated vehicles (ROVs) and autonomous underwater vehicles (UAVs) equipped with sensors, cameras and construction tools can perform some underwater tasks. With advances in control and positioning systems, these vehicles can offer precision in hard-to-reach areas under the water.

Underwater 3D printers can help build or repair pipelines and underwater infrastructure using specialized self-curing concretes and other advanced materials.

Creating Digital Intelligence Underwater

Digital twins of underwater sites can provide precise measurements and visibility where murky water conditions obscure necessary information for construction work.

They can also help teams rehearse and refine operations before sending workers into dangerous conditions. Autonomous underwater gliders can map the terrain for cable installations, using sensors and cameras to plan construction in unexplored undersea areas.

Elevating Planning, Management and Monitoring

With costs high for underwater building, effective design, planning and project management using integrated construction management software enhances team communication, problem-solving and decision-making.

The complexity of building in harsh conditions with specialized tools and materials is better managed with software platforms that can compare plans with actual site conditions, flag inconsistencies and reduce construction errors. Sonar and advanced imaging can monitor the progress and quality of the construction and structural integrity after the hand-off to facilitate ongoing maintenance.

Underwater Construction Offers Expansion Opportunities

Underwater construction stands at the forefront of engineering innovation, helping meet the demand for robust and sustainable underwater infrastructure. By leveraging advanced technologies and specialized materials, companies can build safer and more resilient structures that support modern-day life.

Despite its complexities and risks, underwater construction offers opportunities for construction companies to expand opportunities for growth. Collaboration between contractors, engineers and developers can create projects that meet current needs and pave the way for future advancements. Pushing the boundaries of what is possible in ocean and freshwater construction can yield innovative projects that support sustainable developments in a changing world.

Was this article helpful?

Thank you for your submission.

0%

0%

You voted that this article was . Was this a mistake? If so, change your vote here.

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Categories:

Tags:

Written by

Julia Tell

45 articles

Julia Tell is a freelance writer covering education, construction, healthcare, and digital transformation. She holds a Ph.D. in Media & Communications and has written for publications including Business Insider, GoodRx, and EdSurge, as well as nonprofits, international businesses, and educational institutions.

View profileExplore more helpful resources

Tackling the Top 10 Construction Industry Issues

The construction industry is constantly evolving, bringing both opportunities and challenges. Companies must navigate an array of construction industry issues — from workforce shortages to integrating new technologies into their...

Mission Critical Construction: Strategies for Success

Mission critical construction involves building structures whose functions cannot afford to fail, as any disruptions can lead to significant consequences for society. Keeping data centers, hospitals, power plants and other...

Modular Construction and MEP: A Collaborative Pairing

In an age of supply chain disruptions, workforce shortages, and rising material costs, off-site construction — including modular construction methods and prefabricated materials — is surfacing as a multipurpose solution....

Connected Construction: Transforming the Industry Through Integration

Construction projects are becoming increasingly complex, so companies need to innovate to accurately and profitably complete these modern structures. Connected construction — using technology and data to improve communication, processes...