— 7 min read

Virtual Design and Construction: Technology for Building the Future

Last Updated Nov 15, 2024

Last Updated Nov 15, 2024

Technology is transforming industries from the medical field to the world of entertainment. And construction — although a historically slow industry to adopt change — is no exception. Today, there’s a growing category of virtual design and construction, or VDC for short.

With the rapid rate of the digitalization of construction, deciphering what professionals mean when using terms like virtual design and construction and building information modeling (BIM) interchangeably can be confusing. What the average construction professional should know, though, is that VDC is an umbrella term for forces that are driving change in the industry. Specifically, VDC is a category that includes the digital information and processes that overlay design and construction.

Table of contents

Defining VDC

VDC is a concept that encompasses all of the contemporary technologies that are used to gather, share and track information through the phases of design all the way to construction completion. Any professional who wants to apply virtual design and construction can start by thinking about how they can deploy technology to help support their work.

VDC is a big, broad topic. It encompasses a range of technologies and processes, and experts are still debating the semantics. Since the term VDC was first introduced by Stanford University’s Center for Integrated Facility Engineering (CIFE) back in 2001, people have been trying to pin down its precise definition. CIFE has even updated its VDC overview.

VDC vs. BIM

There’s some debate about the definitions of virtual design and construction and BIM. If VDC sounds like BIM, it’s because there are some definite overlaps here.

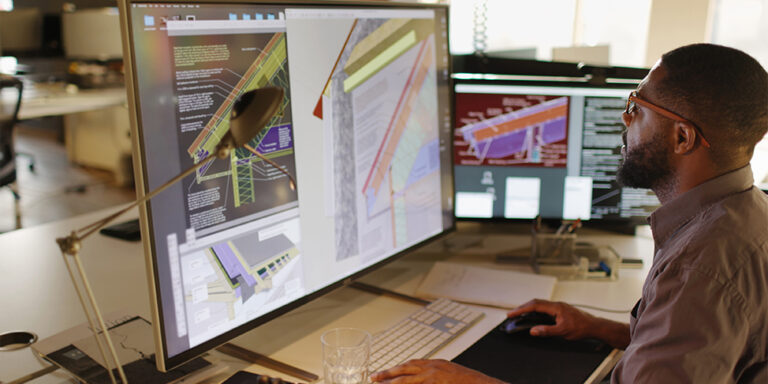

But there are some key differences, too. For starters, BIM has an example most people picture when they think of it (i.e., a 3D model) while VDC lacks such a clearcut representation.

That’s because BIM is just one aspect of VDC and, consequently, easier to pin down. Virtual design and construction is the overarching umbrella term that captures BIM, but it extends past building information modeling to a number of other technologies and processes.

An example: a BIM manager knows about one key aspect of VDC, but is not necessarily an expert in all of the technologies and processes that fall into the purview of VDC.

VDC vs. Building Operations

Sometimes, there is a lack of clarity about where VDC ends. That’s understandable since this is such a far-reaching concept. But there is a clear stopping point for VDC: Virtual design and construction ends when construction ends.

VDC captures a wide range of tools and activities that happen within the preconstruction and construction phases. But once the job is done and construction crews clear off the jobsite, VDC no longer applies.

This can get confusing because there are similar — and even overlapping — technologies. The BIM model used during VDC might feed directly into a digital twin that supports building operations, for example. But the point at which the site shifts from one under-construction to a functional built environment is the point at which VDC ends and other technologies and processes begin.

Technology Within the Realm of VDC

Laying out definitions provides some level of clarity, but most people have an easier time understanding concepts when they’re paired with examples.

This is particularly helpful in the virtual design and construction-BIM differentiation.

Here are just a few examples of things that fall under the umbrella of VDC as it applies to the phases of design and construction:

- Computer-aided design (CAD)

- Building information modeling (BIM)

- Augmented reality (AR) overlays to support proper processes on the jobsite

- Quick-response (QR) codes for on-site access of digital documents, equipment scan-in/out, etc.

- 3D site scans with technologies like lasers, cameras, drones and mobile robots for site analysis and progress tracking

Many designers have been using VDC technology for decades. This tech has progressed rapidly, and today designers frequently use it to get the information they need to best do their jobs. VDC solutions can scan the site for existing conditions, for example, reporting the current state with accuracy that’s within ⅛ of an inch.

The construction side has been slower to adopt new technologies, but the transformation has begun. As large firms — and particularly design-build firms already using virtual tools on the design side — integrate VDC, it’s increasingly common to see this type of tech on the jobsite.

Using VDC on the Jobsite

As virtual design and construction use cases expand to the jobsite, most professionals use it to accomplish two main purposes: progress tracking and risk avoidance.

VDC makes it easier to track time and materials. With strategically placed tools that scan QR codes on hard hats, for example, stakeholders can quickly get an accurate accounting for who’s on site and for how long. This enables stakeholders to compare what’s actually happening with what’s on the schedule, whether that’s a traditional spreadsheet or 4D BIM. They can consequently see, for example, if plumbing contractors didn’t show up as expected, allowing them to pivot accordingly.

VDC isn’t just about managing people, either. It’s also about managing processes. With reality capture, project managers can see if installation is aligning with the drawings or BIM model. They can then identify any deviations earlier, making them easier and cheaper to correct.

Some firms have even advanced to the point that VDC is automating administrative tasks. An owner may use VDC technology to track progress on the jobsite on a daily or weekly basis, for example. Once that tech confirms that certain benchmarks have been hit, their system automatically initiates payment to the appropriate party.

Ideally, virtual design and construction technologies help designers create drawings precisely aligned with what crews will find when they first break ground. Then, it powers accuracy and risk mitigation as construction moves forward. At the same time, when it’s working like it should, it makes tasks easier and faster.

Explore data and trends for building materials prices.

Get the latest U.S. retail prices and view historical trends for common building materials.

An Example of On-the-Job VDC

Material tracking provides an excellent VDC use case.

Some firms have long been using BIM models to automate 3D takeoffs. As VDC expands, that 3D takeoff can be synced with reality capture technology.

With pictures taken on the jobsite, for example, technology can tell that there are 30% fewer doors in the to-be-installed pile and validate that against data from the 3D takeoff. It can then determine that door installation is likely 30% complete. With further VDC tech — whether that’s a laser scanner, someone walking around taking pictures, or a mobile robot like Spot the mobile robot “dog” — stakeholders can validate that estimate.

If door installation falls behind schedule, that deviation gets identified promptly so the necessary changes — like rescheduling with impacted trade partners — can be made.

The Current and Future State of VDC

Since VDC can help stakeholders throughout the design and construction process, one might think professionals would be rushing to adopt it. But the implementation of VDC tech and processes has actually been relatively slow, particularly on the construction side.

Why is this? A few reasons are at play. For starters, new technology is expensive, as is the time allocated to training staff on it. Beyond that, there’s the morale challenge that can come with a requirement to use tools and processes people think are confusing or overly complicated. This overlays an element of distrust in the technologies.

On top of all of this, VDC has been continually changing. What was leading-edge just a couple of years ago might be obsolete today. That has led some construction professionals to determine that they’re better off doing things as they always have.

All of this said, experts predict that change is coming. As virtual design and construction becomes more commonplace, more competitors will come to the field delivering technology, from tangible tools to software. This should drive prices down. Additionally, existing technologies may start to offer VDC functionality (take the 3D scanning capabilities of the iPhone as an example).

More VDC provider competition will also force companies to prioritize user experience, making these technologies easier to use. And as the workforce builds technological competency, implementing further VDC tools should get easier.

At the same time, the aging of the design and construction workforce plays a role. Many newer professionals in the industry grew up in the digital age and consequently expect to use technology to make their jobs easier and more efficient. As younger workers who trust technology replace retirees who have historically been resistant to tech adoption, it wouldn’t be surprising to see VDC explode in the next decade.

Was this article helpful?

Thank you for your submission.

100%

0%

You voted that this article was . Was this a mistake? If so, change your vote here.

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Categories:

Tags:

Written by

Mary Carroll-Coelho

12 articles

Mary Carroll-Coelho is a Product Operations Manager at Procore. A licensed Architect, Mary previously worked for KieranTimberlake, an architecture firm in Philadelphia, in construction and product operations at WeWork, and Director of Customer Success at Willow. She holds a Master of Architecture from the University of Pennsylvania. Outside of work, she volunteers as a mentor in the Spark program.

View profileKacie Goff

54 articles

Kacie Goff is a construction writer who grew up in a construction family — her dad owned a concrete company. Over the last decade, she’s blended that experience with her writing expertise to create content for the Construction Progress Coalition, Newsweek, CNET, and others. She founded and runs her own agency, Jot Content, from her home in Ventura, California.

View profileReviewed by

DJ Phipps

DJ Phipps has spent over two decades working in the building and design industry. He's dedicated to using technology to make work easier and more efficient, with a focus on project management and improving systems. DJ now plays a key role at Procore as a Senior Principal Strategic Product Consultant.

View profileExplore more helpful resources

Types of Construction Specifications: Understanding the Difference

On a construction project, the specification book, often referred to as the “spec book,” typically contains detailed descriptions of the materials, products, systems and workmanship required. The design team —...

Constructability Reviews: Moving From Design to Reality

Before concrete is poured or hammers are swung, a construction project requires the proper scrutiny to determine if the project is even possible. This is where a constructability review comes...

Deciphering Construction Drawing Symbols

In construction, every blueprint and drawing is a complex web of information, distilled into symbols and lines that determine the work executed onsite. For those in the field, understanding these...

Don’t Underestimate the Estimator: Key Responsibilities of Construction Estimators

In construction, the estimator’s role is fundamental to project success. These professionals possess an expansive knowledge of building materials, understand the requirements for various construction projects, engage with up-to-date building...