— 5 min read

Material Management in Construction: A Project Manager’s Guide

Last Updated Mar 12, 2025

Last Updated Mar 12, 2025

Construction materials represent one of the key components for pulling off successful projects, and also one of the biggest expenses contractors face. Optimally managed materials procurement, storage and installation can lead to better budget adherence and efficiency — and less overall waste.

This article will discuss some of the key ideas behind better materials management, and some of the tools and tricks project managers can use to keep materials in line and the project running efficiently.

Table of contents

Examining the Need for Materials Management

At first blush, materials management seems simple: Procurement teams secure prices from suppliers, order what’s needed and site laborers install it.

But there’s far more to the process than first meets the eye. Materials management means planning out the amount of building materials needed and when they should arrive on site. If there are deals for bulk ordering, contracting firms need to decide whether to order enough for the discount only to have to store the excess, which poses more costs and logistical headaches. Finally, when the order arrives at the site, it needs to be placed strategically for easy retrieval and kept safe until it’s installed.

At its best, construction materials management aims to ensure the appropriate materials are purchased at a good price, available when needed and installed as per the original schedule. Effective materials management aligns with project goals by optimizing resources and streamlining processes.

Key Strategies for Effective Materials Management

Construction materials management involves getting the right supplies, in the right amounts, at the appropriate times — all in the most cost-effective way possible. There are a couple of strategies procurement managers can focus on that may improve their ability to control all of the variables.

Forward Planning

Accurate forecasting about project progress and materials delivery timelines can have a huge impact on the overall project, either driving up prices and logistical demands of storage and materials insurance or delaying the project due to late arrival. Analysis of past projects and keeping a close eye on the materials marketplace can help project planners and procurement specialists strike the right timing balance.

Supplier Relationship Management

Suppliers can be seen as valuable partners to contractors throughout the construction process. Not only can they help anticipate timelines, suppliers can strategize with contracting teams on marketplace outlooks to get optimal pricing.

Accurate Material Tracking

During complex projects, materials managers may have a lot different materials in play at any given time. Inventory management and control involves keeping track of all those materials and when they’re required for installation. Construction management software can offer solutions to maintain real-time inventory data for improved tracking and better outcomes.

Explore data and trends for building materials prices.

Get the latest U.S. retail prices and view historical trends for common building materials.

On-Site Material Handling and Storage

Once materials make it to site, contractors need to find a way to store materials securely, where they are handy when needed, but where they won’t be damaged or stolen. Careful planning can help decide on the best place to store materials that won’t impede regular site operations while keeping it close for efficient installation.

Benefits of Optimized Construction Materials Management

Getting clear on materials management can have benefits that extend throughout a construction project. As part of a strategic approach to project management, optimized materials management can help reduce costs and improve efficiency.

Cost Reduction

By managing the supply chain effectively to secure optimal pricing, construction managers can help manage costs and stay within the project budget. And by ordering only the amount of materials needed and getting it to site as close as possible to when it’s required, the contractor can save money and reduce waste.

Better Sustainability

Effective management practices reduce excess materials and prevent waste caused by damage during storage, which can help the project stick to sustainability goals.

Better Schedule Adherence

Construction delays can damage client relationships and increase costs across many processes. Timely availability of materials helps to prevent project delays to ensure schedules are met.

Improved Quality

Good quality materials can lead to better quality results. Materials management includes getting suitable products for the project that can improve its longevity, performance or aesthetic appeal.

Improving Project Management

Imagine a company that decided to make materials management a focus point for improvement across the company.

In order to achieve this goal, they first had to reach out to employees to record and assess the current processes. They created a handbook establishing base knowledge among all employees of what materials management is and how it works, then asked them to record their processes.

When all the processes were analyzed, the company realized that overspending on materials was due to poor forecasting and lack of supplier collaboration. The company then used their construction management software solution to improve inventory tracking, which allowed for earlier and better-informed collaborations with suppliers.

Future Trends in Construction Materials Management

The future of materials management is set to be shaped by technological advancements and sustainability concerns, with some key emerging trends on the horizon.

Advanced Technologies

Innovations like AI and machine learning present the opportunity to further optimize materials management. Blockchain may improve materials tracking by ensuring all parties have access to the same information. Since it can help automate procurement processes, it may be able to improve supply chain efficiency while reducing fraud. Meanwhile, Internet of Things (IoT) data analytics may help teams predict their need for equipment and materials based on past project data.

Sustainable Practices

Eco-friendly materials and processes may gain prominence as the construction industry further prioritizes sustainability. The types and responsible management of materials are a reliable way to achieve greater sustainability and may receive greater focus.

Evolving Supply Chains

As global events continue to reshape supply chain dynamics, teams need to stay adaptable and be able to change course quickly, further demonstrating the benefit of supply management technology to help track, control, analyze and communicate about materials procurement.

Conquering Materials Management With Foresight & Planning

Construction materials management is a key component of successful project management. Insightful materials management stems from accurate forecasting, close material tracking and inventory management and careful maintenance of supplier relationships. Construction managers can help improve the efficiency and effectiveness of their materials management methods by adopting best practices and leveraging technology to enhance efficiency and reduce costs.

Was this article helpful?

Thank you for your submission.

100%

0%

You voted that this article was . Was this a mistake? If so, change your vote here.

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Categories:

Tags:

Written by

Kristen Frisa

67 articles

Kristen Frisa is a contributing writer for Procore. She also contributes to a variety of industry publications as a freelance writer focused on finance and construction technology. Kristen holds a Bachelor of Arts in Philosophy and History from Western University, with a post-graduate certificate in journalism from Sheridan College. She lives in Ontario, Canada.

View profileExplore more helpful resources

Key Benefits of a Construction Procurement Log (With Free Template)

By the time everything is purchased for a construction project, it represents not just a lot of money. It also represents a lot of energy from the teams involved. Getting...

Mastering Construction Resource Management: Strategies for Success

Completing construction projects successfully requires the careful management of various resources: labor, materials, equipment, money, time and information. Since these resources are finite, allocating them wisely is crucial for minimizing...

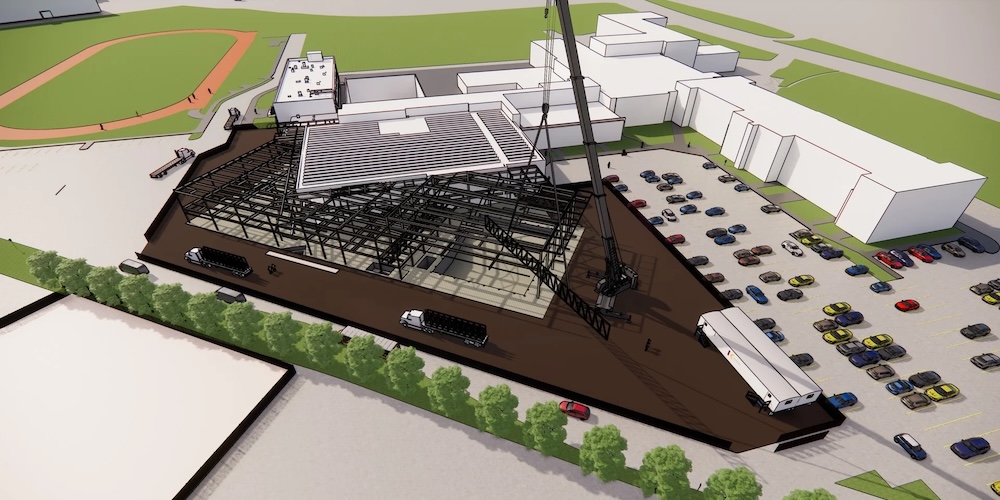

Optimizing Material Logistics & Procurement: Insights from a Sports Facility Project

As an assistant project manager on the Cadigan Wellness Complex Project at Boston College High School, managing material procurement and logistics is one of my primary responsibilities. In addition to...

Wood Frame Construction: Techniques, Benefits & Challenges

Wood-framed structures can be found almost everywhere. If you are in North America, there’s a good chance you are in a wood-framed structure right now, as most single-family homes in...